Dive into trend analyses, technical whitepapers, and case studies to optimize operations and market strategies.

Consumer Electronics mechanical design prototyping

Discover key best practices for streamlined consumer electronics mechanical design prototyping. LKK delivers precision, fast functional prototypes with DFM optimization, cutting development timelines by 30% for global electronics brands.

mechanical design prototyping

Explore mechanical design prototyping from concept to mass production with DFM, simulation, and manufacturing engineering by LKK.

modern product design services

Stop viewing design as a cost. Modern product design services cut BOM expenses by 25% and slash time-to-market. See LKK's DFM playbook in action.

industrial design prototyping

Industrial design prototyping explained: from concept validation to functional products. Learn methods, risks, and how LKK accelerates product development.

industrial design solutions

Uncover the core elements and step-by-step process of industrial design solutions, and learn how LKK’s end-to-end expertise delivers market-ready products efficiently.

contract manufacturing mechanical design services

Learn the exact 8-step process to partner with contract manufacturing mechanical design services and leverage LKK’s award-winning end-to-end product development solutions.

AI Interactive product prototype design

Learn the complete AI interactive product prototype design process from concept to validation, including AI logic, user testing, and system integration.

industrial design process

Master the industrial design process. This guide details all 5 key phases, from research to DFM, with proven strategies from LKK Design experts.

product design company

A product design company like LKK turns ideas into successful products. Learn about industrial design, engineering, manufacturing & the benefits for your business.

industrial design process

A structured industrial design process systematically reduces product failure risk. Learn how a phased approach controls cost, ensures usability, and guarantees manufacturability.

inventing Hardware development

Turn your invention idea into a functional prototype. Our complete guide walks through the critical stages of inventing hardware development, from concept to DFM and beyond.

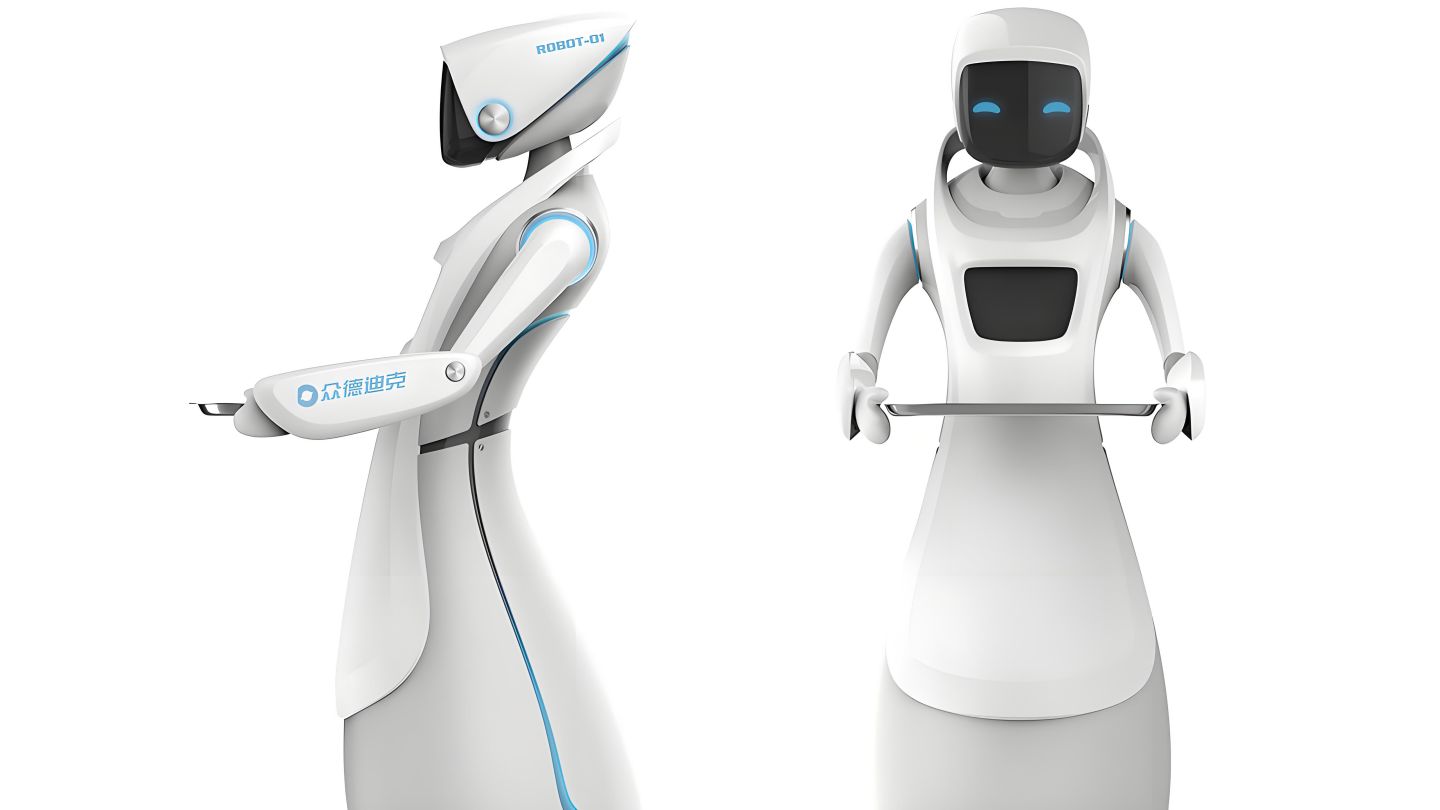

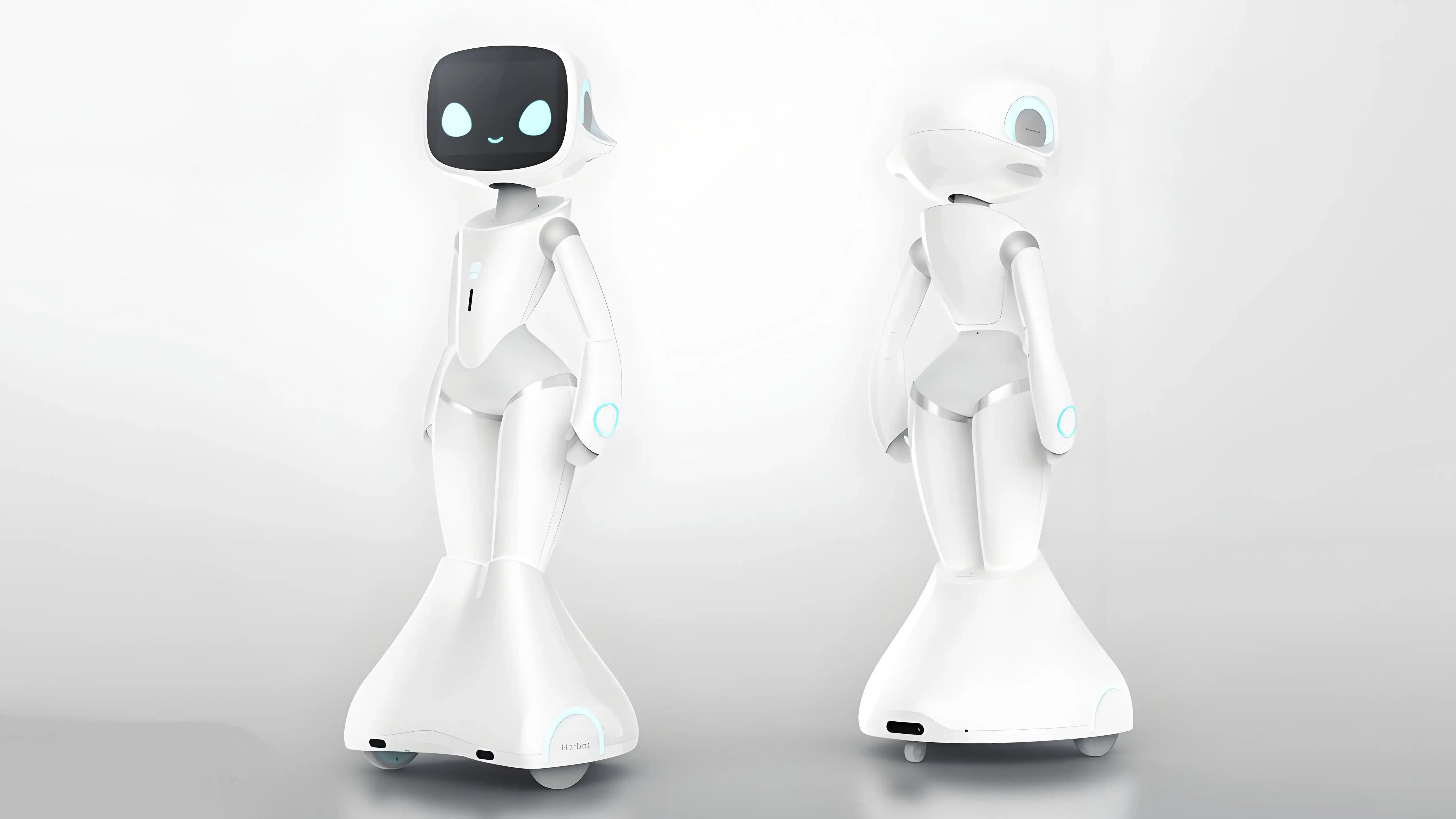

AIOT Design

Explore our AIOT design methodology that powered Yunji Tech's IPO. See how LKK Design uses scenario-driven AIOT design to create category-leading products. Transform your smart hardware idea.

Shenzhen, May 15, 2025 — Within 24 hours of the U.S.-China Geneva Trade Agreement taking effect on May 14, Persona Doctors' executive team arrived at LKK Design's Shenzhen headquarters to relaunch their needle-free injector partnership. This strategic reboot combines precision medical device engineering with integrated consumables solutions, demonstrating cross-border industrial resilience amid evolving trade policies.

Nowadays labor costs are far greater than material costs to a certain extent. For example, engineering personnel with high salaries, managers who are difficult to measure efficiency, etc., all wasted time will be converted into personnel wages.

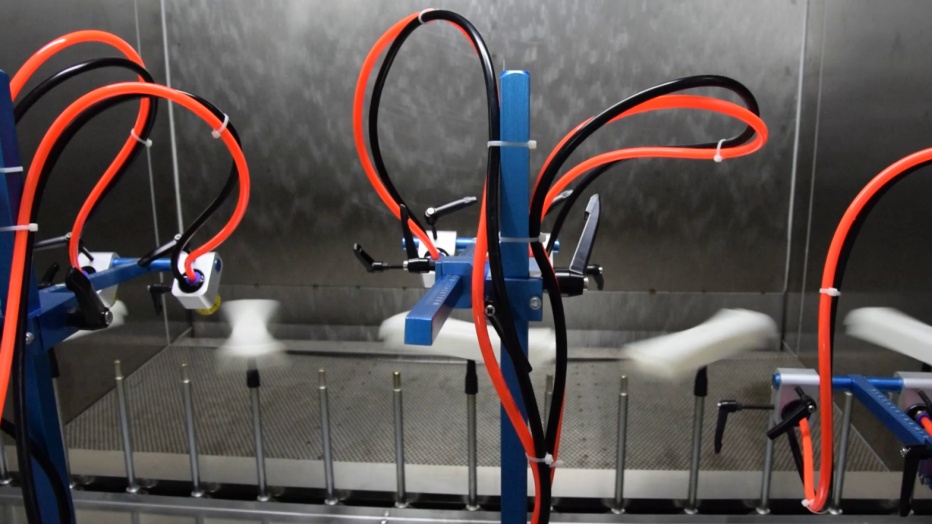

The primer is not completely dried in the curing process, and the position that is not dried after vacuum plating, and the paint will be scraped off by hand

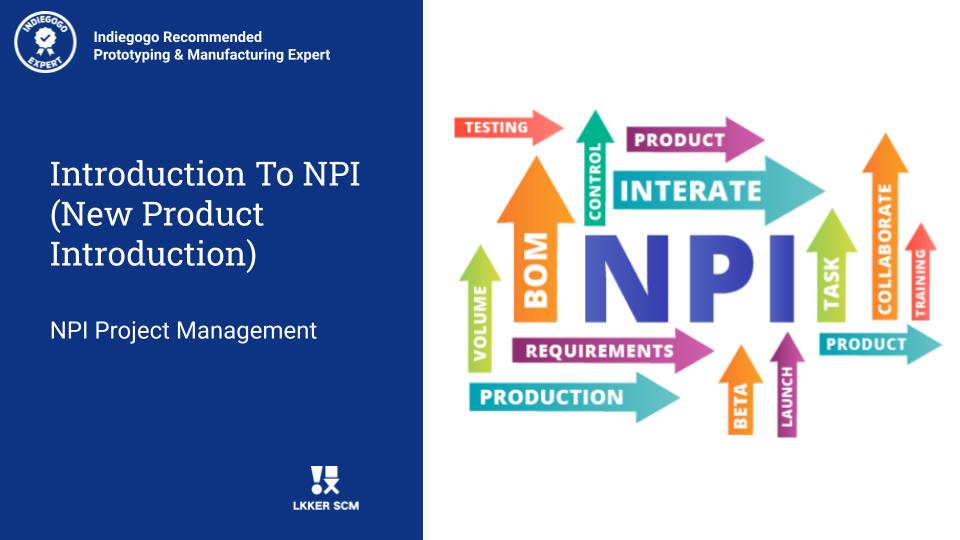

There is an important strategy in new product development (NPI) - Concurrent Engineering. Concurrent engineering also refers as simultaneous engineering, is a method of designing and developing products, in which the different stages run simultaneously, rather than consecutively. It comprehensively considers product characteristics such as manufacturability, affordability, reliability, maintainability, plan-in-advance ability, and marketability in the early design stage to prevent unnecessary occurrences in later production stages. problems or delays.

Some products have a high design requirement and need to have certain protection performance in terms of waterproof, dust-proof, and shock-proof features in order to adapt to various complex and harsh use environments. In the mechanical design of these kinds of products, the mechanical design protection requirements of the product are higher.

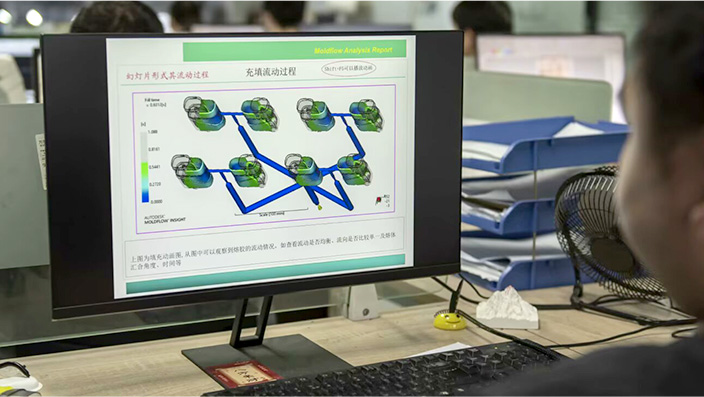

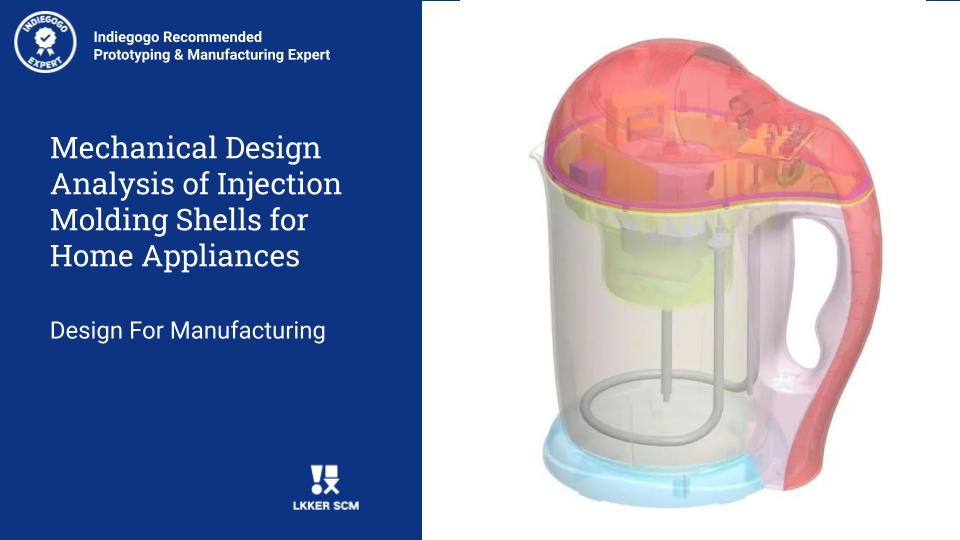

At present, injection molding shells and metal shells are two common shell materials in home electrical appliances. Among them, injection molding shell is widely used due to its advantages of simple process, lightweight, and low cost. The production process requirements of the injection molding shell of home appliances are relatively strict, and it is necessary to pay attention to the parameter setting of temperature and pressure. This blog starts with the design of the injection molding shell of home appliances, discusses the design of the injection molding shell of the soybean milk maker as an example, and analyzes how to solve the injection molding problem of home appliances.

Recently, the No. 6 Changlongshan Pumped Storage Power Station was put into trial operation and put into production. LKK, together with Dongfang Electric Group, jointly built the generator top cover for the Changlongshan Pumped Storage Power Station.

The translucent and pinhole light transmission properties are similar, and they also occur on PC transparent or translucent materials that require cover mold plating. When illuminated with light, the light passes through the coating position.

The design of the medical equipment has put forward higher requirements regarding process efficiency, information accuracy, and service convenience. A comprehensive automated data analysis and management platform that improves medical service experience and resource utilization through aggregation and integration have also emerged under this demand trend in the experiment laboratory field.

There are three different validation tests that a product needs to perform before it goes into mass production: Engineering Validation Test (EVT), Design Validation Test (DVT), and Production Validation Test (PVT). Investing in the EVT, DVT, and PVT process can largely help avoid large-scale product quality issues.

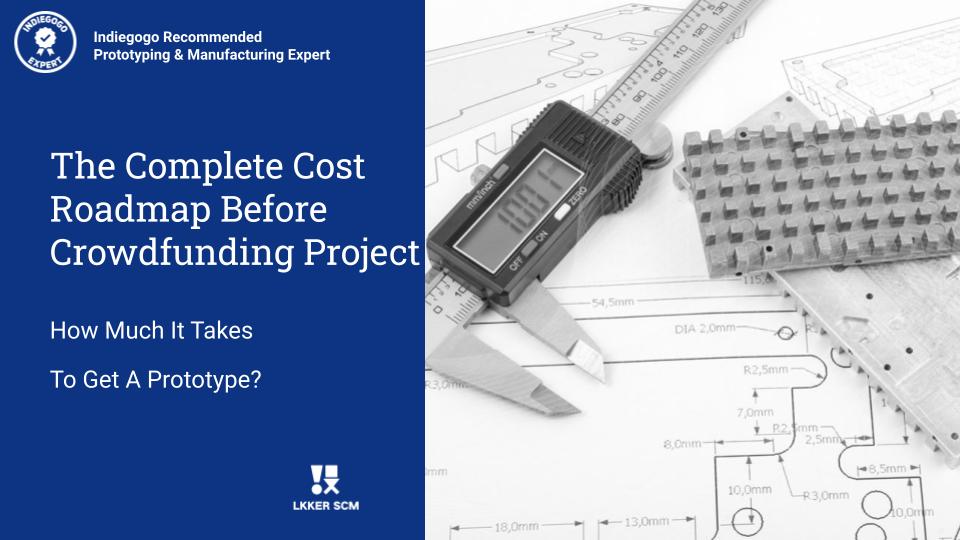

Every year LKK receives a lot of inquiries from inventors about getting help with prototype making for the crowdfunding campaign. Here are three frequently asked questions:

Vacuum plating mainly includes vacuum evaporation, sputtering, and ion plating. They are all used to form various metal and non-metal films on the surface of the product by distillation or sputtering under vacuum conditions, so as to achieve the effect of electroplating.

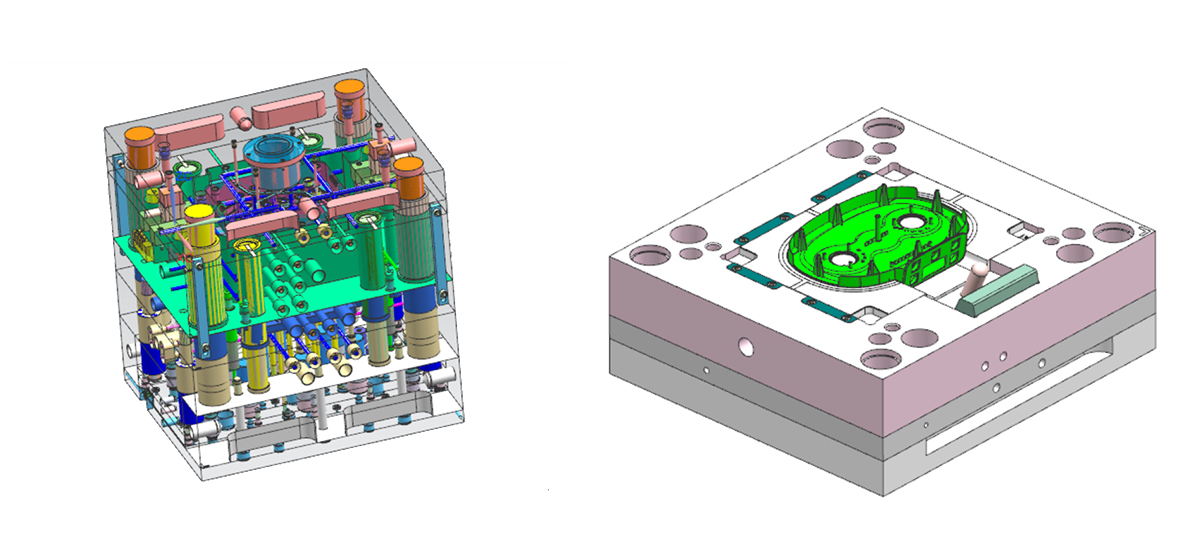

01 Mold appearance

1. The content of the mold nameplate is complete, the characters are clear, and the arrangement is neat.

2. The nameplate should be fixed on the mold foot near the template and the reference angle. The nameplate is reliable and not easy to peel off.

3. The cooling water nozzle should be made of plastic block water nozzle, if the customer requires otherwise, please follow the requirements.

4. The cooling water nozzle should not protrude from the surface of the mold base.

01 Mold appearance

1. The content of the mold nameplate is complete, the characters are clear, and the arrangement is neat.

2. The nameplate should be fixed on the mold foot near the template and the reference angle. The nameplate is reliable and not easy to peel off.

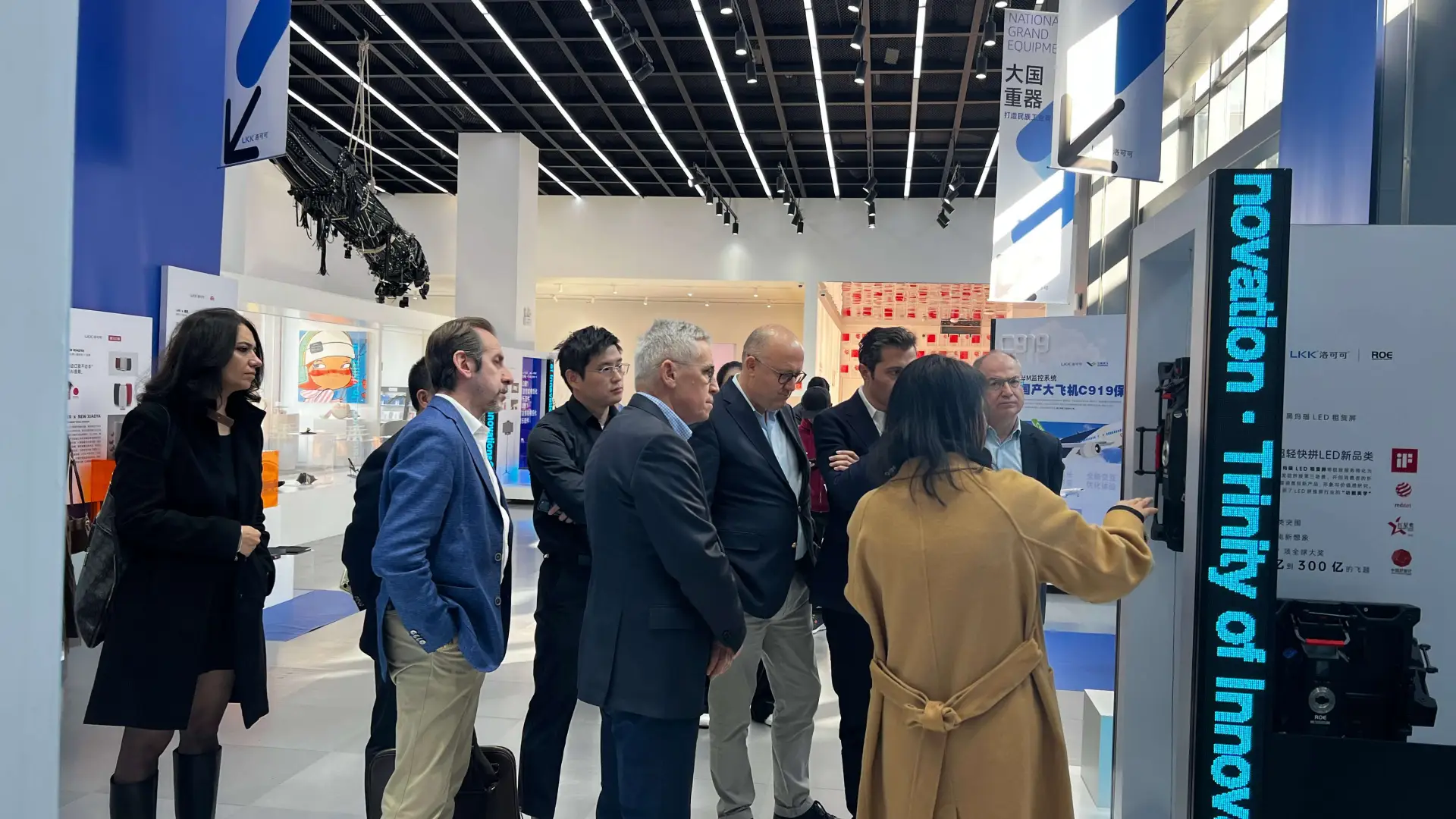

On October 18-21, the four-day "2018 Hong Kong Autumn Mobile Electronics Show" came to a successful conclusion. The LKKER R&D SCM team brought more than 30 innovative products to Hong Kong's largest pavilion - Hong Kong AsiaWorld-Expo along with nearly 3,700 domestic and foreign manufacturers.

As the core task of supplier management, the maintenance of customer relationship brings direct or potential advantages to sourcing enterprises by promoting open exchanges between the two sides and avoiding many potential problems.

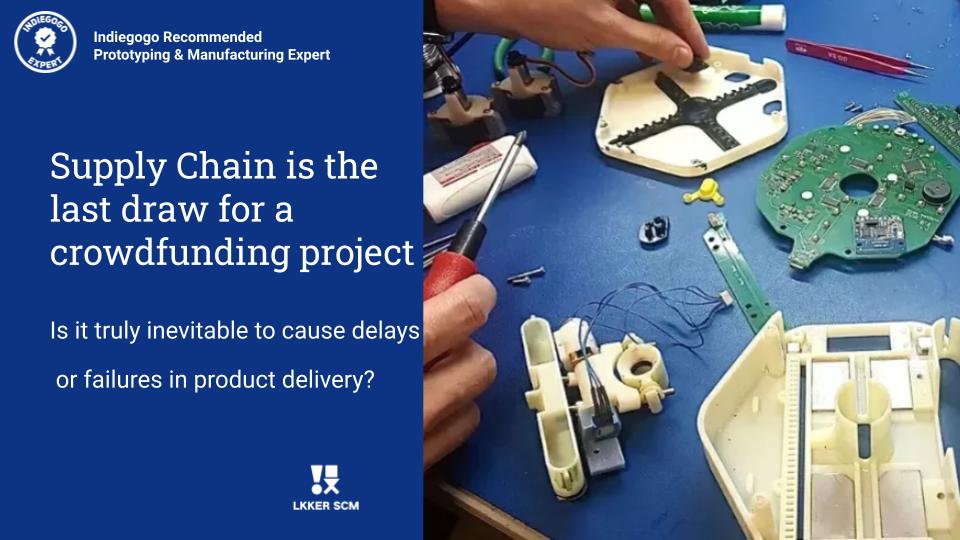

The first thing that came to the mind of many at the mention of the supply chain would be logistics, transportation, loading and unloading. After a great deal of explanation, the response I got was,

"Oh, we have a new term for express delivery?"

"Well, I still don't quite understand what supply chain is."

automotive mechanical design process

Master the automotive mechanical design process. Discover proven DFM strategies to cut costs by 20% and accelerate time-to-market by 30%. Expert guide with real case studies.

contract manufacturing industrial design service

Discover how LKK's integrated contract manufacturing industrial design service cuts product launch timelines by 30%—end-to-end design and manufacturing for fast, market-ready global products.

what is industrial design

What is industrial design? It's the strategic fusion of user needs, business goals & engineering. Discover its process, value, and ROI for your product.

industrial design product

Explore 2026's top industrial design product trends like AI, sustainability & modularity. LKK leads innovation for global manufacturing success.

smart industrial design

Implement smart industrial design with LKK's proven 6-step workflow—feasibility, cost control, and fast timelines for global enterprises.

industrial design company

Selecting an industrial design company is crucial. This guide covers key factors like portfolio, process, and DFM, with insights from LKK Design.

Awards

LKK Innovation Design Group ("LKK Design"), a leading Chinese industrial design company, once again won the 2025 Red Dot Design Award, with 8 products winning awards , including three "Best Design Awards".

Designer Festival

LKK Design Hosts Inspiring 321 Designer Festival to Spark Creativity

LKK Design proudly concluded its annual 321 Designer Festival today, a vibrant celebration dedicated to honoring its creative talent. The event combined collaborative games, brain-teasing challenges, and gourmet treats, fostering teamwork and reigniting artistic passion among designers.

Medical Exhibition

Shenzhen, October 15, 2024 — The 90th China International Medical Equipment Fair (CMEF) concluded successfully at the Shenzhen. LKK Design stood out as a beacon of innovation and forward-thinking design。capturing the attention of industry professionals and visitors alike. The four-day event attracted nearly 4,000 exhibitors and professional visitors from over 140 countries and regions。showcasing LKK Design's deep expertise and groundbreaking advancements in medical product design.

At the beginning of 2019, LKK and Saite Robot jointly developed an intelligent delivery robot (AGV) suitable for different hospitals to solve the time-consuming and labor-intensive situation of multiple handling of materials in different areas and the easy spread of bacteria problems.

Storion Energy, as a brand of green energy storage power that mainly focuses on the European and American markets, is an green energy storage device that arises when the market faces the high electricity prices.

The iF Design Award is one of the most prestigious design awards in the world and has been held in Germany since 1953. The iF Design Award logo signifies good design and is a mark of quality for both consumers and designers.

Award

The article introduces Red Dot Design Award History, Red Dot Design Award tracks and sub-tracks, and how to apply for Red Dot Design Award as well as how much it costs to apply for Red Dot Design Award.

When we choose suppliers, of course, we want the suppliers to be excellent and loyal. This is similar to choosing a partner. However, for many companies, the reality is: that excellent suppliers are usually not loyal enough, and loyal suppliers are usually not good enough, so they continue to develop suppliers, and constantly changing suppliers have become a helpless choice for these companies.

For well-known or giant companies, almost all suppliers are not strong suppliers, because the company's annual procurement volume and industry status will make all suppliers flock to them, and these suppliers want to enter the company's supplier resource pool even if they break their heads. However, the topic of strong attitude supplier management is a topic that medium and small companies may encounter.

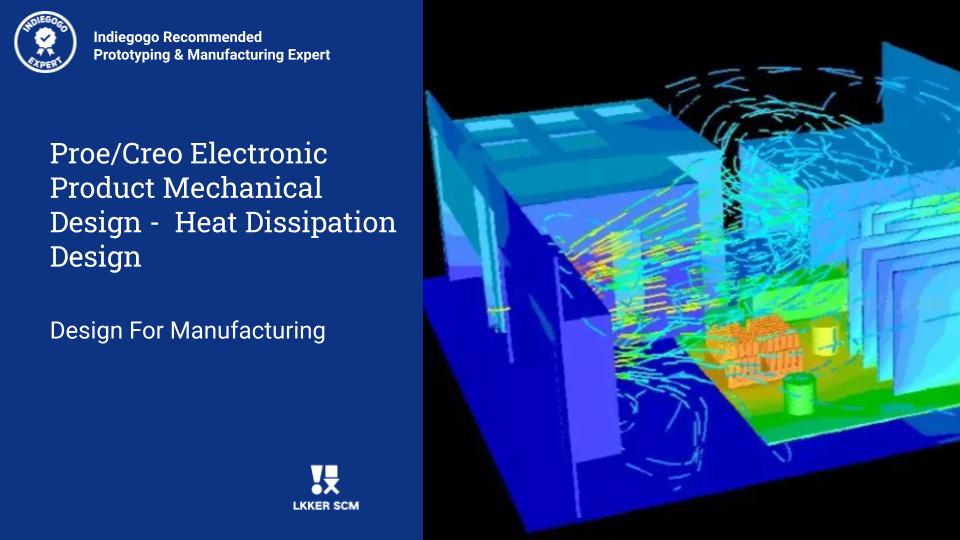

Heat dissipation design is to take various mechanical design measures to control the working temperature of electronic products according to the thermal characteristics and heat transfer principles of electronic components so that it is within the allowable range to provide good performance for chip level,

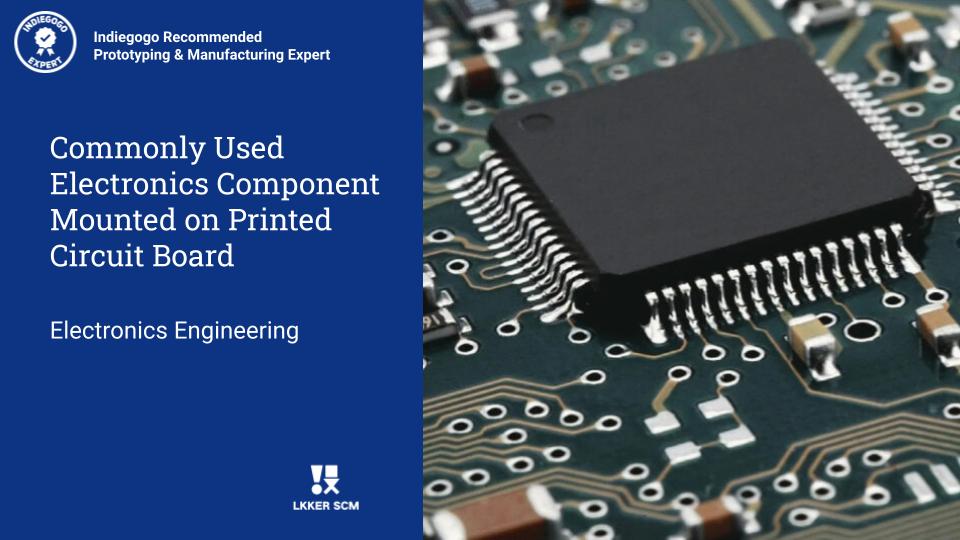

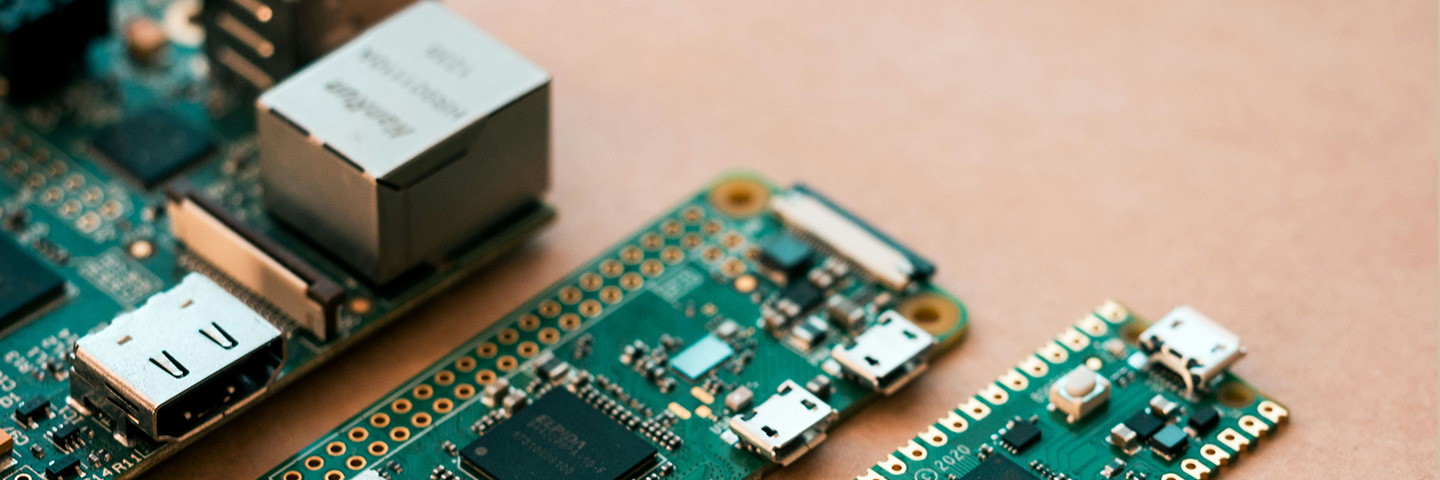

Here are commonly used electronics components mounted on a printed circuit board:

Stacked boards

The complete product stacking board includes PCB, handset, LCD screen, keyboard, microphone, speaker, camera, motor, battery connector, battery, TF card holder, TF card, SIM card holder, SIM card, antenna, USB connector, Various electronic components, product chips, etc.

Concept

At this stage, it's all about a great idea.

POC: Proof of Concept

If it is a new product, it is very important to verify the idea first. For the initial idea verification and testing, there are many resources available to assist. Product developers and Makers with basic technical capabilities can use off-the-shelf "development boards" or various methods to quickly simulate the prototype of the product.

NPI (New Product Introduction) EVT Workflow

1. Participate in the Kick off Meeting to understand the background of the project, the main features of the product, and the functions implemented.

2. Participate in the establishment of the project, fully understand the name of the project, the customers of the project, the effect to be achieved by the project, and know the development plan of the project.

It is expected that contract product development will become a major outsourcing trend in the next 10 years. The basis of this model is that technical talents can be introduced according to different cost expenditure changes, allowing startups to focus on its core expertise and business development. If a company decides to use an outsourcing model to develop a product, it may benefit a lot.

Cost is the core part of a product. The level of cost determines the company's profit to a large extent. Cost control starts from the beginning of product design.

1. When selecting materials, on the premise of satisfying the function, try to use materials with low prices

The buckle position mainly refers to the buckle position of the upper shell and the lower shell. When considering the number and position of the buckle, it should be considered from the overall and external dimensions of the product. It is required to have an average number and a balanced position. The buckle located at the corner should be as close to the corner as possible to ensure better fitting at the corner. Seam problems are prone to occur at corners.

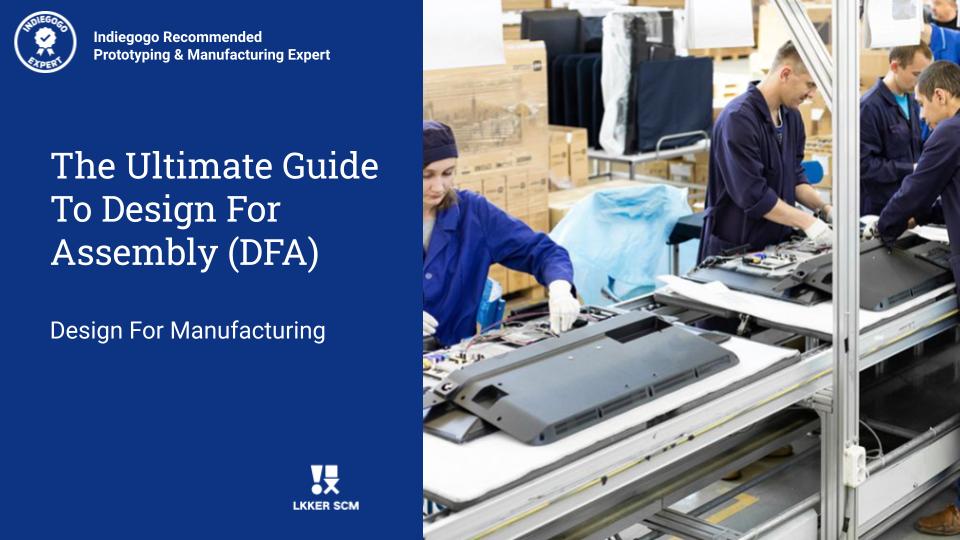

The Concept of Assembly

Assembly refers to the assembly of components into a product that can achieve the quality of a variety of products. The concept of assembly can be derived from the meaning of assembly:

a) Put the components together;

b) Realize the corresponding functions;

c) Achieve great quality of the product.

Startup product development services

Explore complete startup product development services from idea to mass production. Learn how LKK reduces risk and accelerates time to market.

advanced product development

Master advanced product development strategy. Discover how to accelerate innovation by 30% while reducing risk. Proven frameworks from 10,000+ successful product launches.

product design prototyping

Discover LKK's step-by-step product design prototyping guide from concept to mass production. Master DFM, PCBA, and prototyping for faster time-to-market.

How to choose best product development company

Strategic guide to selecting a product development partner. Learn the 2 essential criteria for evaluation and a proven step-by-step selection process.

electric design invention

Master electric design invention with LKK's 9-step workflow—feasibility, cost control, and compliance for global innovators.

mechanical design invention

What is mechanical design invention? It's the engineering process of turning ideas into functional, reliable, and manufacturable physical products. Learn the key stages here.

modern product prototype

Discover what a modern product prototype is, its key purposes, and the technologies used to create functional models for design validation and testing.

product design and development

A card-thin device is redefining professional workspaces, showcasing how industrial design transforms artificial intelligence into tangible business value.

On December 7th, invited by Wang Tan, Vice president of XPENG AEROHT, I had the honor to visit the famous Guangdong Huitian Aerospace Technology Co., LTD., namely XPENG AEROHT.

On May 30, 2023, the fifth Imagination Conference, themed "Category Breakthroughs AI Breakthroughs", was successfully held in Shanghai, jointly organized by the LKK Design Group. From symbols to oracle bones, from agriculture to modern times, from ignorance to civilization, humanity has never stopped its progress.

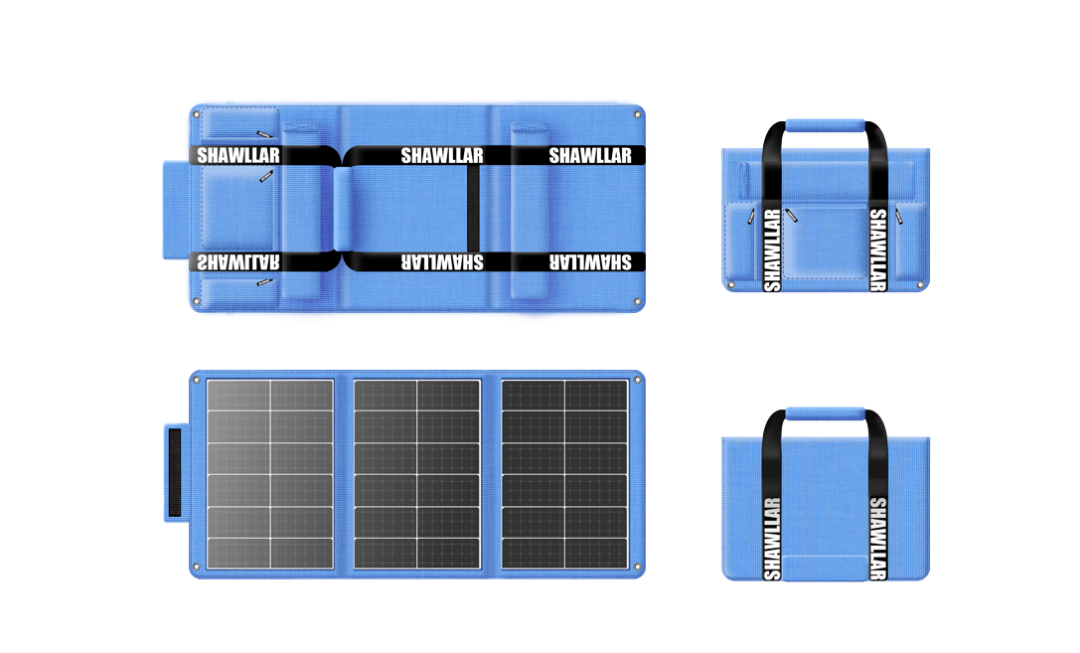

In the third year of the epidemic, people's strong desire for outdoor activities has been prompted. The suburban safari with close distance, low risk, sparse crowd, and good environment has become the most popular travel activity in the past two years.

In the face of new market demands, LKK and Shawllar jointly created a portable energy storage power for outdoor camping activities - the "Explorer" series of photovoltaic solar power bags.

Oil and gas price is highly related to world economies and the financial system. As the basic energy that can affect the prices of all aspects of life, oil and gas are scarce resources and the exploration equipment is still laborious, inefficient, and expensive to use.

We receive thousands of product requests every year, and thousands of customers talk to us about products. We find that many companies prefer to talk about the product itself, the function of the product, the expected design stunning effect of the product, the technology of the product, and the effect of the product realization, but companies with high success rate prefer to talk about the market positioning of the product, purchase scenarios, sales channel characteristics, why this product is made, competitive advantages and detailed user portraits.

The "Wentian" lab module was successfully launched in July 2022. As an important part of the "Tiangong" space station, the "Wentian" lab module is the second largest lab module launched to the space station after the "Tianhe" core cabin module. LKK was once again involved in the product design and manufacturing project for the aerospace industry and successfully contributed to the development of the airspace station.

New Product Introduction (NPI) Service work with you from design stage to production to improve the product development project performance and help you launch the new product successfully to the mass production stage by EVT, DVT, and PVT.

With the development of the product design industry, the demand for mechanical design is also increasing, so in this blog, we will disclose to you what mechanical design service a design company can provide.

In product mechanical design, there are still many experiences and methods, which are summed up by LKKERSCM mechanical designers and mechanical engineers. These experiences and skills cannot be learned in books. In this blog we disclose the tips or rules for product mechanical design

The meaning of the split line

It is commonly found in a narrow and shallow slot and designed for mechanical function, process needs, or decorative effects on plastic products, sometimes it is called a "cosmetic line" or "decoration line".

The EV car industry has developed rapidly worldwide. China, as a leader in the EV car industry, comes up with a lot of EV car brands such as Xpeng, Nio, Hiphi, etc. EV charger, as an accessory product for electric vehicles, is also becoming popular with the rise of the EV car industry.

A lot of crowdfunding projects fail to deliver the product. Some inventors hold strong responsibility to deliver the product, but it usually still takes a long time. Unlike movie or art crowdfunding projects, the industrial product campaign comment area often appears a lot of impatience and complaints about the delay, refund requests, or even accusations of liars.

Due to the rapid expansion and development of the industrial Internet industry, the demand for clean energy storage equipment and clean energy applications is growing. The energy storage product market has become highly homogeneous and nowadays industry players have to pay higher attention to product design.

In today's world, hardware innovations have become more accessible and frequent. Traditional electronics products nearly have no secret technology and boundaries that can keep other electronics engineers from copying anymore. The main battlefields of hardware have been shifted to industrial design and key advantage on function components such as patented chips or sensors.

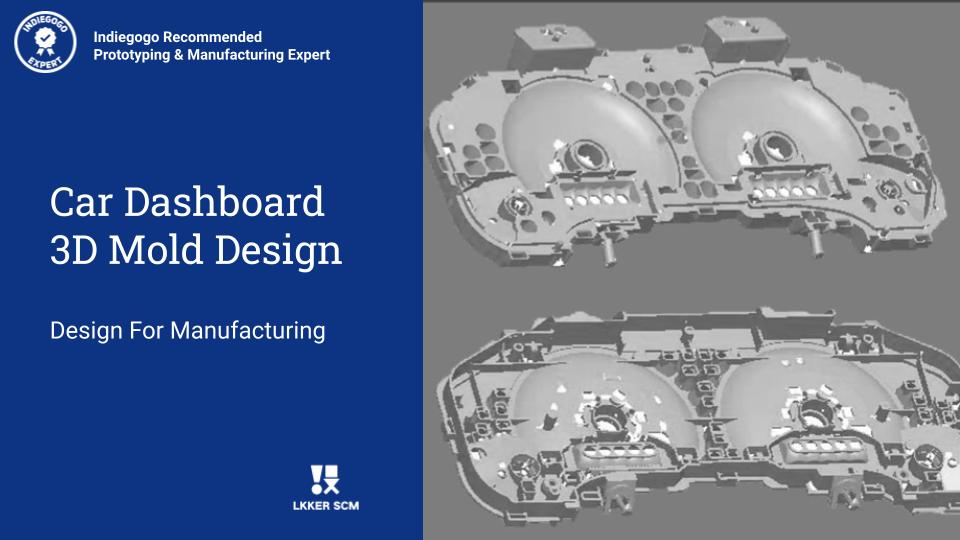

Mold Making is an important step in product development. Car Dashboard mold design case study to understand how to conduct mold design.

We use cookies to ensure that we give you the best experience on our website. By clicking "Accept All", you consent to our use of cookies. Learn more.

Please fill out the form and we'll get back to you shortly.

Your submission has been received !

Thank you for your submission.

We will get back to you within 24 hours and appreciate your patience.

Enter your details to receive the toolkit for free.