In today’s global manufacturing landscape, businesses of all sizes rely on contract manufacturing and mechanical design services to turn product concepts into manufacturable, market-ready goods. The key to success is not just choosing a provider, but collaborating effectively to streamline design-to-production, control costs, and speed up time-to-market.

For 21 years, LKK Consulting Design Group has been a global leader in end-to-end contract manufacturing mechanical design, serving 100+ Fortune 500 clients, launching 10,000+ products across 20+ industries, and holding China’s largest portfolio of international design awards. With 800+ designers, 13+ regional design centers in China, and 5000+ vetted global supply chain partners, LKK has refined an 8-step collaboration framework that eliminates bottlenecks and drives consistent results. This guide breaks down that process, with actionable insights from LKK’s decades of industry expertise.

The Growing Need for Specialized PartnershipsIn-house design and manufacturing teams often face critical limitations: limited DFM (Design for Manufacturing) expertise, high overhead, outdated equipment, and no access to global supply chains. These gaps lead to unmanufacturable designs, cost overruns, delayed launches, and low production yields—issues that specialized contract manufacturing mechanical design providers are built to solve.

A top-tier provider combines mechanical engineering expertise with end-to-end manufacturing capabilities, designing products for production from the start and leveraging global supplier networks to cut costs. This single-point partnership eliminates the chaos of coordinating multiple vendors, the biggest cause of project delays in product development.

Key Pain Points Solved by Expert ProvidersPartnering with a specialist like LKK resolves the most common product development pain points: design bottlenecks from limited in-house engineering, cost overruns from fixed in-house manufacturing costs, slow time-to-market from limited prototyping capacity, supply chain disruptions, regulatory compliance gaps, and IP theft risks.

How LKK Redefines the PartnershipLKK’s user-centric, end-to-end model sets it apart from generic providers that offer only design or manufacturing. LKK integrates mechanical design, industrial design, electronics design, prototyping, and contract manufacturing into a seamless process, with 800+ engineers working side-by-side with clients to align every decision with functionality, cost, and production feasibility. With a track record of 592+ international design awards (Red Dot, iF Design) and zero IP breaches since 2004, LKK delivers balanced solutions for innovation, quality, and cost efficiency.

Clarity on your in-house limitations, project objectives, and budget/timeline is the foundation of a successful contract manufacturing mechanical design partnership. This step ensures alignment with your provider from the start and avoids costly miscommunication.

Audit Your Internal ResourcesConduct a straightforward audit of your team’s capabilities: Do you have DFM-trained mechanical engineers? Access to prototyping and manufacturing equipment? Vetted global suppliers? The ability to manage regulatory compliance (CE/FCC/FDA)? For most businesses, the answer to one or more is no—and LKK’s free project assessment service identifies these gaps and aligns your goals with its end-to-end capabilities.

Define Quantifiable Project ObjectivesVague goals lead to vague results. Outline specific, measurable objectives for your product: core mechanical functionality and durability standards, per-unit production cost targets, fixed launch timelines, required global certifications, and production scale (small-batch vs. mass manufacturing). LKK translates these into trackable KPIs—such as 6-week prototype delivery and <1000 PPM defect rates—and aligns its entire process with these metrics.

Map Out Budget & Timeline ConstraintsTransparency about budget and timeline lets your provider optimize the design and manufacturing process for your needs. A tight timeline may prioritize LKK’s parallel development and rapid prototyping, while a tight budget focuses on DFM optimization and modular design. LKK’s financial and project management teams create realistic, fee-free budgets and timelines to keep projects on track.

Not all providers have the technical expertise, industry experience, or global capabilities to deliver your product successfully. Cutting corners in vetting leads to costly mistakes, delays, and poor quality—so establish non-negotiable criteria and validate every potential partner thoroughly.

Establish Non-Negotiable Screening CriteriaNarrow your search with criteria tailored to contract manufacturing mechanical design: dedicated industry-specific mechanical engineering and DFM expertise, end-to-end manufacturing capabilities (prototyping to mass production), global supply chain access, core quality certifications (ISO 9001/13485/TS16949), robust IP protection processes, and verifiable client references in your industry.

Verify Specialization, Certifications & Global ScaleMechanical design is industry-specific: a consumer electronics specialist cannot design medical devices or industrial robots, which require strict durability and compliance standards. LKK’s 800+ engineers specialize in 20+ industries, with dedicated teams for medical, smart home, industrial robotics, and aerospace.

LKK holds all core quality certifications (ISO 9001/13485/14000/TS16949) and has a dedicated compliance team that integrates CE/FCC/FDA pre-testing into every step—including prototyping—ensuring your product is certification-ready for mass production. Its 5000+ vetted supply chain partners span China, Vietnam, India, Mexico, and Singapore, with a 95%+ on-time delivery rate for global clients.

Once you’ve shortlisted providers, initiate contact with a comprehensive project brief—the blueprint for your partnership—and protect your intellectual property, one of your most valuable business assets, before sharing any confidential information.

Prepare a Comprehensive Project BriefA strong brief gives your provider all the information needed for a tailored solution, including: product overview and functional requirements, existing design concepts or material preferences, target markets and required certifications, budget/timeline and per-unit cost targets, production scale, and brand/aesthetic guidelines. LKK provides a custom brief template to ensure no critical details are missed, streamlining the initial consultation.

Ask the Right Questions in Your First ConsultationValidate the provider’s expertise with targeted questions: What is your DFM optimization process? How fast do you deliver functional prototypes (with pre-testing)? How do you control production costs? What IP protection measures do you have? How do you manage supply chain disruptions? Do you offer post-production support? LKK answers these transparently, with real metrics and case studies to back its capabilities.

Protect Your IP with a Comprehensive NDAIP protection is non-negotiable. Sign an NDA that outlines ownership, confidentiality, and breach liability before sharing design concepts or specifications. LKK has a zero IP breach record since 2004, with ironclad measures: NDA signing for all clients, encrypted secured development zones, data encryption for project files, 100% client ownership of all patents, and dual-source procurement for critical components to eliminate supplier IP risks.

DFM optimization is the most critical phase of contract manufacturing mechanical design. A design not optimized for production leads to costly rework, low yields, and delayed launches—this step ensures every design decision is rooted in manufacturability.

Joint Concept Design & Mechanical Architecture PlanningLKK’s process starts with collaborative ideation, where mechanical engineers translate your vision into a technical mechanical system architecture, including detailed architecture maps, KPIs, and core component alignment. For complex products, LKK creates 3D engineering models with GD&T (Geometric Dimensioning and Tolerancing) annotations to ensure manufacturing precision.

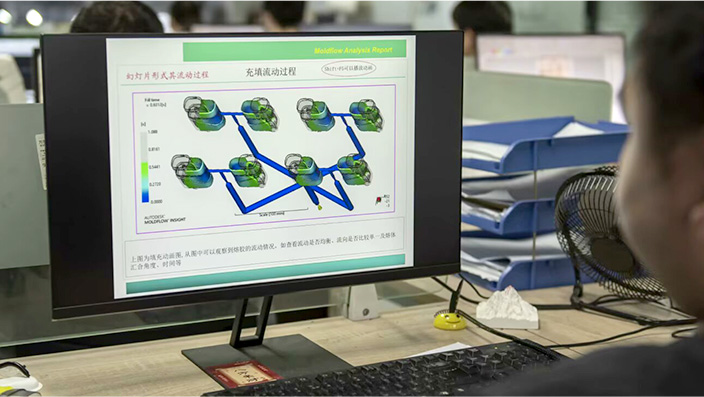

Prioritize DFM to Eliminate Production RisksDFM is the cornerstone of LKK’s service, optimizing designs for efficient, cost-effective production by refining wall thickness, draft angles, and tolerances; eliminating unnecessary components; selecting readily available materials; and reducing manufacturing processes. LKK’s DFM process includes 3D model reverse analysis and a risk matrix report that identifies and fixes flaws before prototyping.

LKK’s Industry-Leading DFM ExpertiseLKK’s 800+ mechanical engineers are DFM specialists, and the company offers a free DFM Cost Optimization Playbook to all clients. Its modular design approach cuts mass production costs by 25% on average, with material efficiency delivering an additional 20% in cost savings. After DFM optimization, LKK delivers an initial design proposal for your review and approval, iterating until it aligns with your functional, cost, and aesthetic goals.

Prototyping turns your approved 3D design into a functional physical product, validating performance, durability, and manufacturability through rigorous testing. The goal is to fix design flaws early—before they become costly production issues.

Select the Right Prototype TypeChoose a prototype type based on your goals: rapid prototyping (3D printing/CNC) for fast, cost-effective form/fit validation; or engineering prototypes (industrial manufacturing) for rigorous EVT/DVT testing. LKK recommends a phased approach, balancing speed and cost efficiency for optimal results.

Conduct Structured EVT & DVT TestingLKK integrates Engineering Verification Test (EVT) and Design Verification Test (DVT) into every prototyping process: EVT validates core mechanical functionality and component compatibility, with issue tracking to fix flaws early; DVT tests for durability, environmental resistance, and industry compliance (critical for medical/industrial products). Both tests include detailed reports, and LKK’s engineers iterate on the prototype based on findings to ensure production readiness.

LKK’s Rapid Prototyping AdvantageLKK delivers functional engineering prototypes in 6 weeks (with CE/FCC pre-testing)—30% faster than the industry average—thanks to parallel development (design, prototyping, and pre-testing happening simultaneously) and in-house pilot lines and prototyping facilities. This speed lets clients conduct early market testing and accelerates the path to mass production, a game-changer for tight time-to-market goals.

Once the prototype passes EVT/DVT testing, finalize the design and prepare for mass production with technical documentation delivery, supply chain planning, and Production Verification Testing (PVT)—a small-batch pilot that validates manufacturing scalability.

Final Design Sign-Off & Technical DocumentationFormal design sign-off is accompanied by comprehensive technical documentation, the blueprint for mass manufacturing: 3D GD&T engineering drawings, a detailed Bill of Materials (BOM), manufacturing/assembly SOPs, Engineering Change Notices (ECNs), and compliance test reports. This documentation ensures consistency across all manufacturing facilities and suppliers.

Supply Chain Planning & Vetted Supplier MatchingSupply chain planning is key to cost-effective scalability, a core LKK strength. Its supply chain team leverages 5000+ vetted global partners to match your product with the best raw material, component, and manufacturing suppliers—based on cost, quality, and regional market needs. For critical A-level components, LKK uses dual-source procurement to eliminate supply chain disruptions and provides an Approved Vendor List (AVL) for ongoing production.

PVT – Pilot Production for ScaleLKK conducts a small-batch PVT (100–500 units) to validate manufacturing processes for scale, testing production line efficiency, component compatibility, QC/defect rates, and cost compliance. PVT identifies and fixes process flaws before full mass production, ensuring a seamless transition and a >98.5% production yield rate—LKK’s standard for all clients.

Mass production is where your concept becomes a commercially available product, and LKK’s end-to-end QC process ensures consistent quality, while its global manufacturing capabilities deliver scalable production for any volume (1,000–1,000,000+ units).

Seamless PVT to Mass Production TransitionLKK’s in-house pilot lines and manufacturing engineering expertise enable a smooth PVT-to-mass production handoff. Its engineers optimize production lines for efficiency and cost control—including workstation layout simulation, ergonomic optimization, and lean production strategies (e.g., SMED rapid changeover)—reducing production time and improving worker safety. LKK’s 12 core manufacturing processes (CNC, injection molding, SMT, sheet metal, etc.) are in-house or via vetted partners, ensuring a single-point partnership for all production needs.

Full-Cycle QC & QALKK’s comprehensive QC/QA process spans every production stage: incoming material inspection, in-process random sampling, 100% final product functional/durability testing, and continuous improvement by tracking and analyzing defects to refine processes. This rigorous approach delivers a defect rate <500-1000 PPM—far below the industry average—and a >98.5% yield rate.

Production Monitoring & On-Time DeliveryLKK’s PMC (Production and Material Control) team monitors production in real time, providing clients with regular updates on volume, quality, and timelines. With a 95%+ on-time delivery rate, LKK also manages international shipping and logistics for global clients, ensuring products reach target markets on time and in compliance with local import/export regulations.

Contract manufacturing mechanical design is a long-term partnership, not a one-time service. The best providers offer comprehensive post-production support to optimize your product, reduce costs, and scale production over time— a core LKK differentiator.

Post-Production Technical SupportLKK’s engineering team provides rapid ECNs for design adjustments, production process troubleshooting, and re-testing/certification for design changes. This responsive support minimizes production disruption and keeps your product competitive in the market.

Ongoing Supply Chain OptimizationAs your product scales, LKK’s supply chain team continues to optimize your network: negotiating volume discounts with suppliers, identifying cost-effective materials/components, optimizing production lines for higher volume, and aligning manufacturing with regional market demand to cut shipping costs. LKK clients typically see an additional 10–20% cost reduction for subsequent production runs.

Build a Long-Term Product Development PartnershipMany of LKK’s clients partner for ongoing product development, from initial launches to iterations and new product lines. LKK’s deep understanding of your brand, industry, and market needs makes it a valuable long-term partner, scaling its contract manufacturing mechanical design services to match your business growth.

Partnering with LKK offers unique advantages that translate to faster time-to-market, lower costs, higher quality, and reduced risk—advantages generic providers cannot match. The table below outlines LKK’s core strengths, metrics, and real-world business impact.

Table : Key Advantages of Partnering with LKK for Contract Manufacturing Mechanical Design Services

| Core Advantage | LKK’s Core Metric/Deliverable | Real-World Business Impact |

| Time Efficiency | Parallel development + in-house pilot lines; functional prototypes in 6 weeks (CE/FCC pre-tested); 30% faster timelines | Accelerated market entry; early competitive advantage |

| Quality Excellence | ISO 9001/13485/14000/TS16949; APQP planning; <500-1000 PPM defect rate; >98.5% yield rate | Consistent high quality; reduced rework/warranty costs |

| Cost Leadership | Free DFM Playbook; modular design; 5000+ supplier network; 25% lower mass production costs; 20% cost efficiency | Reduced development spend; higher profit margins |

| Risk Mitigation | 0 IP breaches since 2004; dual-source procurement; CE/FCC/FDA/ROHS compliance support | Eliminated IP theft; minimal supply chain disruptions; seamless global certification |

| Global Scale & Integrated Resources | 13+ China design centers; 5000+ global supply chain partners; 800+ dedicated mechanical engineers | Scalable production; global supply chain flexibility |

| End-to-End Expertise | Full Concept→EVT→DVT→PVT→MP process; 12 core manufacturing processes | Single-point partnership; streamlined communication; no multiple vendors |

LKK’s expertise is proven by 10,000+ successfully launched products across 20+ industries. The table below highlights LKK’s most notable contract manufacturing mechanical design projects, with core services and key achievements.

Table : Real-World Success Cases – LKK’s Contract Manufacturing Mechanical Design Projects

| Industry | Client/Project Name | LKK’s Core Contract Manufacturing & Mechanical Design Services | Project Achievements & Key Highlights |

| Medical Device | Ceribell AI EEG | DFM optimization; supplier matching; mold design; pilot production; QC/certification | Fast-tracked production for medtech startup; medical device compliance; seamless prototype-to-commercial scale |

| Smart Home | Siemens Smart Home System | Precision mechanical design; mass production optimization; supply chain integration | $1B+ revenue growth in 1 year; industry-leading smart home hardware; award-winning design |

| Consumer Electronics | Huawei PixLab X1 | Mechanical design; rapid prototyping; DFM; mold manufacturing; mass production | Redefined touch-print home printing; CE/FCC certified; >98.5% production yield |

| Medical Robotics | Vicen+E Surgical Robot & Cart | Custom precision mechanical design; prototype validation; assembly & testing | Industrial-grade surgical durability; ISO 13485 compliance; ergonomic/functional optimization |

| AI Robotics/EdTech | Oti-Robot AI Interactive Companion | Mechanical design; electronics integration; mass production; QC/certifications | Red Dot Design Award; robust child-safe structure; on-time global launch |

| Medical Equipment | Anke Surgical Assisted Navigation System | Custom mechanical design; DFM optimization; supply chain matching | Enhanced surgical precision; 20% production cost reduction; ISO 13485 compliance |

Each case demonstrates LKK’s ability to deliver custom contract manufacturing mechanical design solutions tailored to industry and client needs, from category-defining smart home hardware to life-saving medical devices. LKK’s cross-industry expertise lets it apply proven strategies across sectors, a key strength for diverse client needs.

LKK prioritizes transparency in every partnership, and these are the most frequently asked questions about its contract manufacturing mechanical design services, with direct answers from its expert team.

Q1: What product development stages does LKK cover?

A: LKK’s full-cycle solution covers Concept Definition → EVT/DVT Prototyping → PVT Pilot Production → Mass Manufacturing → Post-Production Support. Since 2004, we’ve launched 3000+ products across 30+ industries with this process.

Q2: How does LKK accelerate time-to-market?

A: Parallel development and in-house pilot lines cut timelines by 30%, with functional prototypes (CE/FCC pre-tested) delivered in 6 weeks—far faster than the industry average.

Q3: How does LKK control development and manufacturing costs?

A: DFM optimization, modular design, and our 5000+ vetted supplier network reduce mass production costs by 25% on average, with a free DFM Cost Optimization Playbook for all clients.

Q4: What IP protection does LKK offer?

A: We have zero IP breaches since 2004, with NDAs, encrypted development zones, data encryption, 100% client patent ownership, and dual-source procurement for critical components.

Q5: What quality systems does LKK implement?

A: ISO 9001 + APQP planning, with built-in DFM/EMC pre-compliance checks, delivering a <500-1000 PPM defect rate and >98.5% production yield rate. We also hold ISO 13485 (medical) and TS16949 (automotive) certifications.

Q6: Can LKK support global regulatory compliance?

A: Yes. Our dedicated compliance team integrates CE/FCC/FDA/ROHS/ISO pre-testing into every step, ensuring your product is certification-ready by mass production for seamless global market entry.

Outsourcing to a contract manufacturing mechanical design provider is a transformative decision for product development, eliminating in-house bottlenecks, reducing costs, and accelerating time-to-market. LKK’s 8-step framework—refined over 21 years—delivers a repeatable, results-driven process that streamlines collaboration and reduces risk for every project, from startups to Fortune 500 enterprises.

LKK’s 800+ dedicated mechanical engineers, 5000+ vetted global supply chain partners, end-to-end service model, and track record of 10,000+ launched products make it the trusted partner for contract manufacturing mechanical design across every industry. Unlike generic providers, LKK doesn’t just design and manufacture your product—it partners with you to turn your vision into market success.

LKK’s free project assessment service will help you identify in-house gaps, align your product goals with its capabilities, and create a realistic budget and timeline. Whether you’re developing a medical device, smart home hardware, industrial robot, or consumer electronic, LKK’s expertise ensures your product is engineered for manufacturability, quality, and growth.

Website: www.lkkerscm.com

Email: lkkerscm@lkkdesign.com

Phone: +86 (755) 23608253

Address: F10 CEEC Building Of Upperhills, Huanggang Road 5001, Huafu Street, Futian District, Shenzhen, China

We use cookies to ensure that we give you the best experience on our website. By clicking "Accept All", you consent to our use of cookies. Learn more.

Please fill out the form and we'll get back to you shortly.

Your submission has been received !

Thank you for your submission.

We will get back to you within 24 hours and appreciate your patience.

Enter your details to receive the toolkit for free.