The marketplace is a graveyard of brilliant ideas that failed to become successful products. Studies consistently show that a significant percentage of new product launches fail, often due to preventable issues: a misunderstood user, a flawed design, an unexpected manufacturing cost, or a simple lack of market appeal. For entrepreneurs and established companies alike, this landscape makes product development feel like a high-stakes gamble. The central question for any innovator is: how do we systematically de-risk this journey? The answer lies not in luck, but in methodology. A professional, structured industrial design process is fundamentally a risk-mitigation engine. It transforms subjective guesswork and chaotic creation into a managed, predictable sequence of validation gates, each designed to identify and neutralize specific threats to your product's success before they become catastrophic.

Before understanding how it de-risks, we must define what it is. A structured process is more than a timeline; it's a disciplined, phase-gate system.

Unlike an ad-hoc approach where design happens in a black box, a structured process is transparent and sequential. It consists of distinct phases, each with clear objectives, deliverables, and "gates." Proceeding to the next phase requires a formal review and approval of the previous phase's outputs. This ensures no critical step is skipped and that decisions are based on evidence, not instinct.

This structure is built on three pillars:

User-Centricity: Every phase is informed by real user needs and behaviors, ensuring the product solves a genuine problem.

Iteration: Low-cost, rapid cycles of prototyping and testing within each phase allow for refinement before heavy investment.

Cross-Functional Alignment: It forces early and continuous collaboration between design, engineering, marketing, and business stakeholders, aligning everyone around a single vision.

This is not theoretical. Leading design firms operationalize this. For instance, LKK Design employs a defined, user-centric process spanning approximately 6-8 weeks, moving through five critical stages from Research to DFM Optimization. This isn't just a service offering; it's a tested risk-mitigation framework.

Let's dissect a typical structured process to see how each phase acts as a targeted risk filter.

The Action: This is the foundation. It involves in-depth user interviews, ethnographic studies, competitive product tear-downs, and trend analysis. The goal is to define the problem space thoroughly.

The Risk Mitigated: Building a product based on internal assumptions rather than market reality. This phase directly attacks the risk of creating something nobody wants or that already exists in a better form.

In Practice: A firm like LKK Design dedicates the first week of its process exclusively to this. By grounding the project in empirical data on user behavior and competitive landscapes, they ensure the ensuing design work has strategic direction and market relevance from day one.

The Action: Designers generate a wide range of conceptual solutions—not just one. This is expressed through sketches, storyboards, and mood boards that explore different aesthetic languages, user interactions, and form factors.

The Risk Mitigated: Rushing into development with the first idea (which is rarely the best). It also mitigates stakeholder misalignment by providing multiple, tangible directions for discussion and choice, moving debates from the abstract to the concrete.

In Practice: LKK's process specifies the delivery of 3-5 distinct concept schemes for client review. This structured divergence ensures creative exploration and provides a strategic portfolio of options, allowing clients to make an informed choice that balances innovation with brand and business goals.

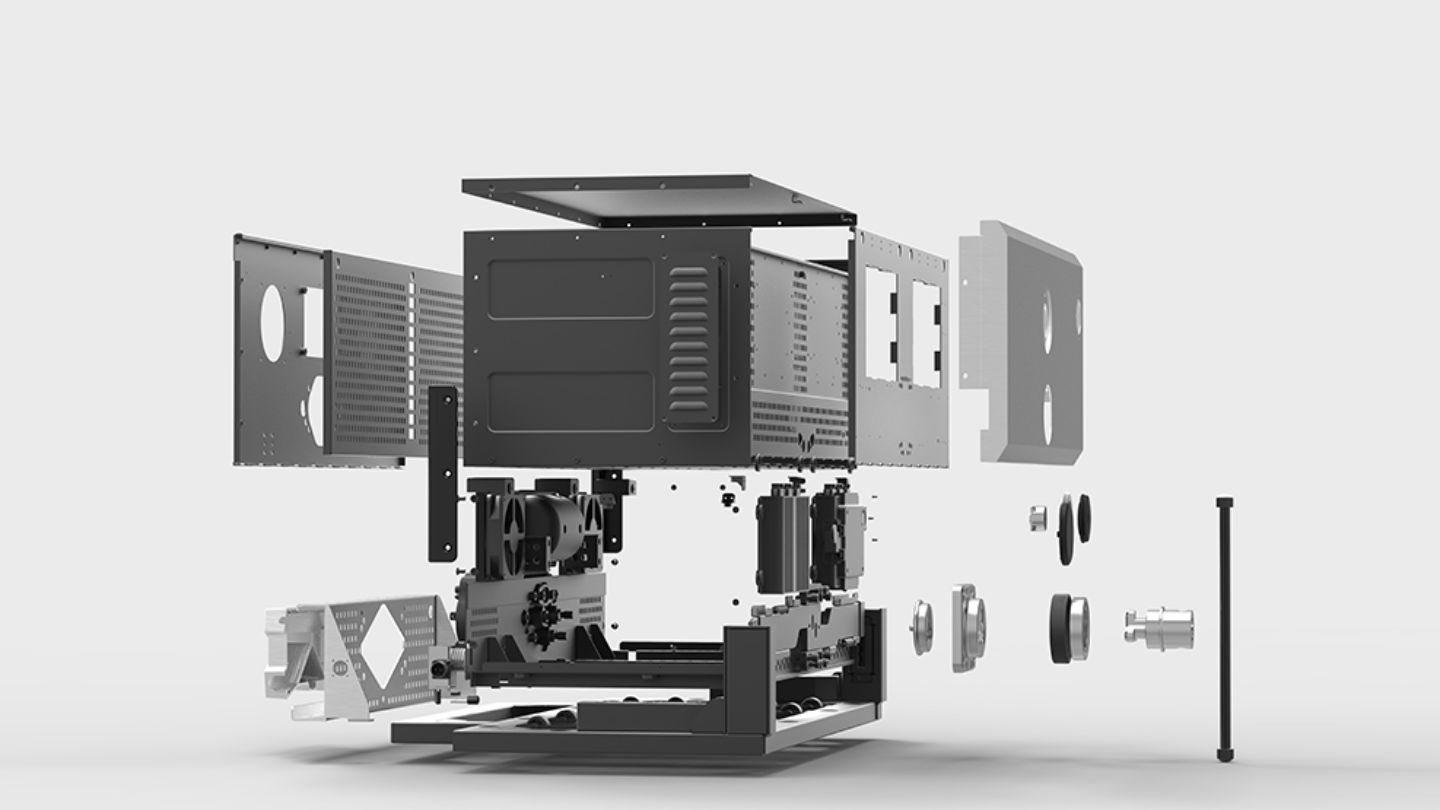

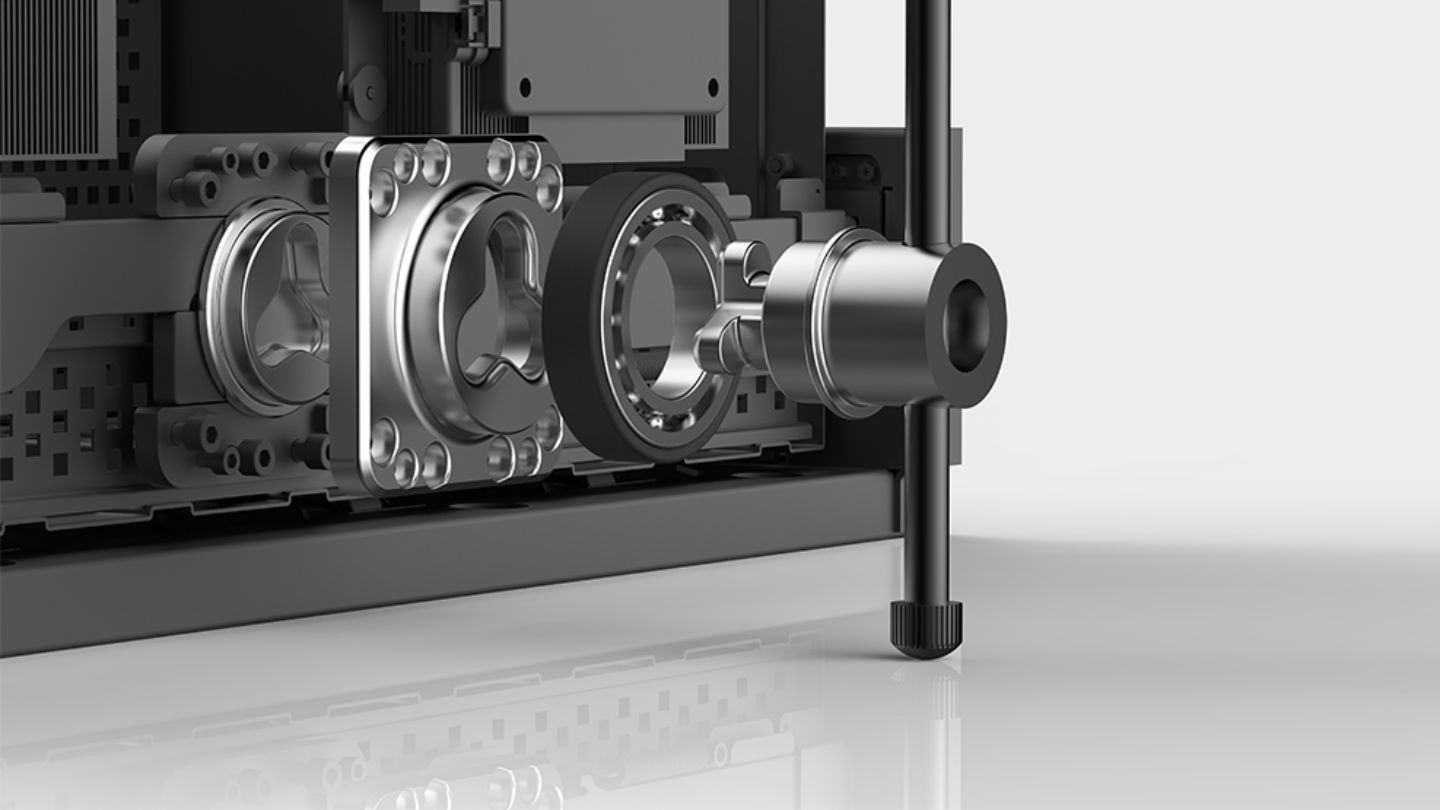

The Action: The selected concept is developed into precise 3D CAD models. These models are then used to create high-resolution renderings for marketing feedback and, crucially, functional prototypes for hands-on testing.

The Risk Mitigated: The catastrophic risk of discovering that a beautiful sketch is uncomfortable to hold, difficult to assemble, or mechanically unsound after investing in production tooling. Prototypes reveal ergonomic flaws, usability issues, and engineering challenges that are invisible on a screen.

In Practice: This phase is where digital meets physical. LKK's workflow includes creating both high-res renderings for aesthetic validation and functional prototypes to test mechanics and assembly. This tangible output transforms subjective opinion into objective data about the design's real-world performance.

The Action: Colors, Materials, and Finishes (CMF) are strategically specified. This goes beyond picking a color; it involves sourcing material samples, testing finishes for durability, and evaluating tactile feel.

The Risk Mitigated: The risk of a product that looks cheap in person or uses a material that is unavailable for mass production. CMF defines perceived quality and user emotion. Getting it wrong can doom an otherwise well-engineered product.

In Practice: A professional process doesn't leave CMF to chance. LKK's methodology, for example, delivers 3 refined CMF options accompanied by physical material samples. This allows clients to see and feel the quality, ensuring the final specification aligns with the brand's premium perception and is logistically feasible.

The Action: The design undergoes a rigorous Design for Manufacture (DFM) review. Engineers analyze every part for moldability, assembly sequence, tolerance stacking, and cost-effectiveness. The design is refined for the factory floor.

The Risk Mitigated: The single largest financial risk: creating a "works-like" prototype that is impossible or prohibitively expensive to manufacture at scale. This phase prevents costly tooling reworks, production delays, and unprofitable per-unit costs.

In Practice: This is the critical handoff from design to production. LKK's final phase is a joint engineering review for manufacturability. This directly addresses the core client concern highlighted in their own analysis: "Is the concept feasible, and what will it cost?" It ensures the elegant design is also a viable commercial product.

The value of this phased approach is measured in cold, hard business metrics.

A fundamental rule of product development is that the cost of fixing a problem increases exponentially as you move closer to production. A change in the concept phase costs little—perhaps a few hours of sketching. The same change found during mass production could cost hundreds of thousands in new tooling and delayed launch. A structured process is designed to find and fix issues as early as possible.

Table: The Escalating Cost of Change in Product Development

| Phase | Relative Cost of a Major Change | Primary Risks Being Mitigated |

| Research & Concept | 1x (Base Cost) | Market misread, strategic misalignment. |

| Detailed Design & 3D Modeling | 10x | Ergonomic flaws, aesthetic failures, basic engineering issues. |

| Prototyping & Testing | 100x | Functional failures, user experience problems, material performance. |

| Pre-Production (Tooling) | 1,000x | Manufacturing feasibility (DFM), assembly errors, quality control issues. |

| Mass Production | 10,000x+ | Recall-level failures, brand damage, unsustainable unit economics. |

An ad-hoc process is plagued by unknowns, leading to feature creep, scope drift, and missed deadlines. A structured process with defined phases, deliverables, and gates creates a predictable roadmap. It allows for accurate budgeting and scheduling because the work, and its associated costs, are segmented and managed.

Without structure, decisions often default to the "HIPPO" (Highest Paid Person's Opinion). A phased process replaces opinion with evidence: user research data, prototype test results, CMF samples, and DFM reports. This creates a shared, objective foundation for decisions, building consensus and team confidence.

The benefits of structure become stark when contrasted with the alternative:

The "Just Make It Pretty" Trap: Treating industrial design as a late-stage cosmetic service. This leads to engineers designing a functional box that designers are then asked to "skin," resulting in compromised aesthetics, poor usability, and higher manufacturing costs to retrofit beauty.

Skipping Phases: A client demanding to jump straight to 3D modeling to "save time" is, in fact, taking enormous risk. They are building on an unvalidated foundation, almost guaranteeing costly rework later.

The Communication Breakdown: Without phased deliverables and review gates, stakeholders operate with different mental models of the product. This misalignment only surfaces late in the game, causing conflict, delays, and compromised products.

In the end, a world-class industrial design process is far more than a sequence of tasks to create a shape. It is a strategic business tool for de-risking innovation. It systematically identifies and neutralizes market, design, engineering, and manufacturing risks through disciplined validation at every step. It transforms product development from a risky gamble into a managed, confident investment.

For companies seeking to bring a new product to market, the choice is clear: embrace chaos and chance, or partner with a framework designed for success. Firms like LKK Design offer more than design talent; they provide the very risk-mitigation engine described here. Their documented, user-centric, phase-gate process embodies the strategic partnership needed to navigate the complex journey from idea to successful product, ensuring that concerns about feasibility, cost, and timeline are not anxieties, but variables that are actively managed and resolved.

We use cookies to ensure that we give you the best experience on our website. By clicking "Accept All", you consent to our use of cookies. Learn more.

Please fill out the form and we'll get back to you shortly.

Your submission has been received !

Thank you for your submission.

We will get back to you within 24 hours and appreciate your patience.

Enter your details to receive the toolkit for free.