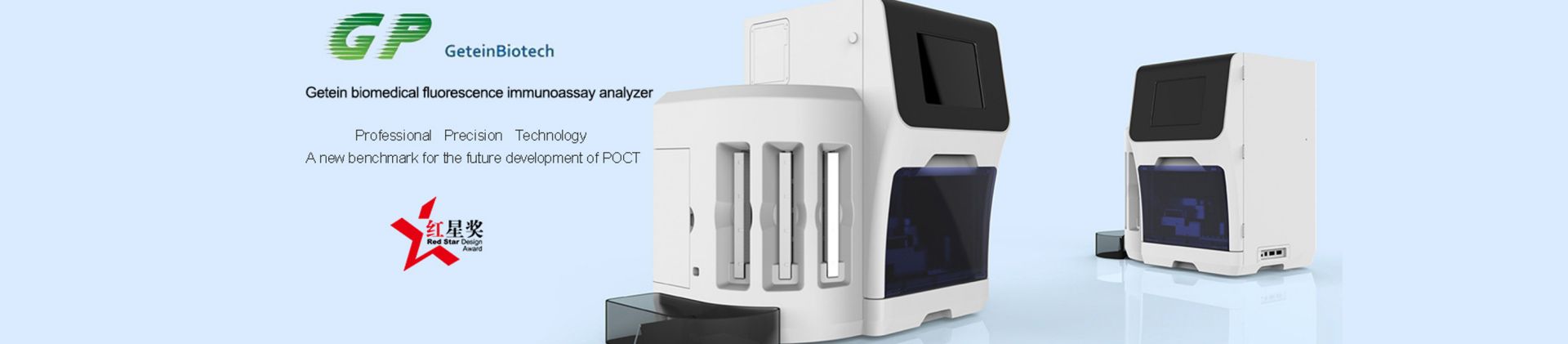

A Fluorescence Immunoassay Analyzer designed for Getein Biotech

Getein Biotech is a high-tech enterprise specializing in the R&D, production, and sales of in-vitro diagnostic (IVD) reagents and medical devices. Guided by the business philosophy "Pursue Excellence and Deliver Health," the company is committed to providing high-quality products for the global healthcare industry.

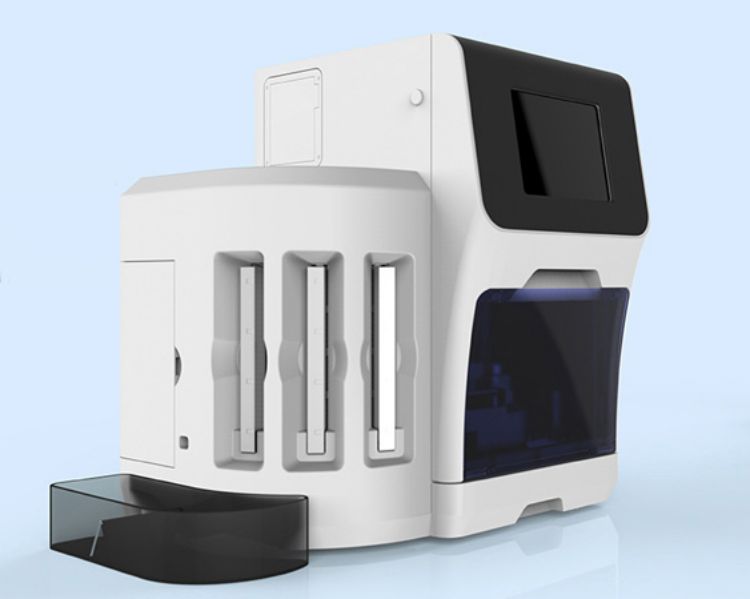

LKK Design partnered with Getein to redesign the Getein1600 Fluorescence Immunoassay Quantitative Analyzer. This critical medical device works with dedicated test kits to quantitatively detect a wide range of biomarkers from human serum, plasma, whole blood, and urine. Its applications include clinical diagnosis for cardiovascular diseases, infections, and renal function, making reliability and usability paramount.

The Getein1600 analyzer is used in demanding environments like hospital laboratories and emergency rooms. Getein's goal was to enhance the instrument's overall user experience and operational reliability without compromising its analytical precision.

Key objectives for the redesign included:

Enhancing Usability: Improving key interactions, such as test kit placement and waste disposal, to streamline workflow for medical staff.

Ensuring Reliability: Solving specific mechanical issues, particularly waste card jamming in the disposal slot.

Optimizing for Manufacturing: Implementing a modular architecture to simplify assembly, reduce production costs, and avoid expensive mold modifications.

Elevating Aesthetics: Creating a modern, professional, and trustworthy appearance that aligns with contemporary medical device standards.

Our human-centered design process involved deep research, thoughtful industrial design, robust engineering, and rigorous validation.

Design Research

Our team began with immersive research in clinical settings, observing healthcare professionals as they loaded samples, handled test kits, and managed waste. We identified key pain points, with waste card jamming emerging as a critical issue affecting device uptime and user frustration. This insight directly informed our core design strategy.

Industrial Design

The exterior design language was crafted to communicate "professional, clean, and approachable." We used clean forms and continuous surfaces to create a robust and trustworthy aesthetic. A color palette of white accented with medical blue was chosen to evoke cleanliness and reliability.

We meticulously refined human-machine interaction details. An inward chamfer on the test kit entry guide ensures smooth and intuitive loading and unloading, reducing handling errors and improving workflow efficiency.

Mechanical Structure Design

The mechanical redesign was pivotal to solving the project's key challenges.

Waste Card Management: We introduced an innovative chevron baffle at the bottom of the waste card slot with a 50-degree tilt angle. This simple yet highly effective feature actively guides discarded test cards to both sides, preventing pile-ups and jams without interfering with the robotic pick-up mechanism.

Modular Architecture: The entire instrument was re-architected into modular sub-systems (e.g., optical detection, sample processing, waste management). This modularity streamlined the assembly process, significantly reduced manufacturing costs, and facilitated easier maintenance and future iterations.

Prototyping and Testing

We built high-fidelity appearance models and functional prototypes using 3D printing and CNC machining. The waste disposal mechanism underwent extensive testing cycles. We iteratively adjusted the chevron baffle's angle and slot dimensions until we achieved a "zero-failure" rate in waste card handling, validating the design's robustness before mass production.

Through this collaboration, LKK Design delivered more than just a new aesthetic. We provided a comprehensive product solution that delivered tangible value:

Enhanced User Experience: The intuitive kit handling and jam-proof waste system minimize operational interruptions for medical staff.

Improved Reliability & Uptime: The redesigned mechanical systems ensure consistent performance in critical diagnostic settings.

Reduced Manufacturing Costs: The modular design simplified the production process, lowering assembly costs and avoiding the high expense of new mold creation.

By analyzing the product from all aspects—appearance, function, assembly, and usage environment—we truly put ourselves in the shoes of the customer and the end-user. The result is a human-centered fluorescence immunoassay analyzer design that helps Getein Biotech deliver on its mission to "Deliver Health."

We use cookies to ensure that we give you the best experience on our website. By clicking "Accept All", you consent to our use of cookies. Learn more.

Please fill out the form and we'll get back to you shortly.

Your submission has been received !

Thank you for your submission.

We will get back to you within 24 hours and appreciate your patience.

Enter your details to receive the toolkit for free.