Injection Molding

Precision Injection Molding Manufacturing, Powering Mass Production Efficiency

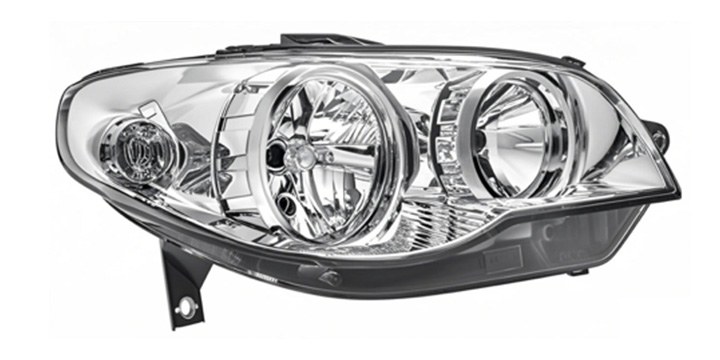

Injection molding rapidly produces complex parts by injecting molten plastic into steel molds under high pressure. Applied in consumer electronics, medical, and automotive sectors.