We transform prototypes into mass-producible goods through process innovation, supply chain orchestration, and quality system design.

30% projects face cost overruns due to poor DFM | 68% delays caused by supply chain mismatches | 15% yield loss from unoptimized

3D Model Reverse Analysis (Draft angle / Wall thickness / Tolerance analysis.)

Mold Complexity Rating System (Slider quantity vs. cost evaluation.)

Deliverable: DFM Risk Matrix Report (with improvement prioritization).

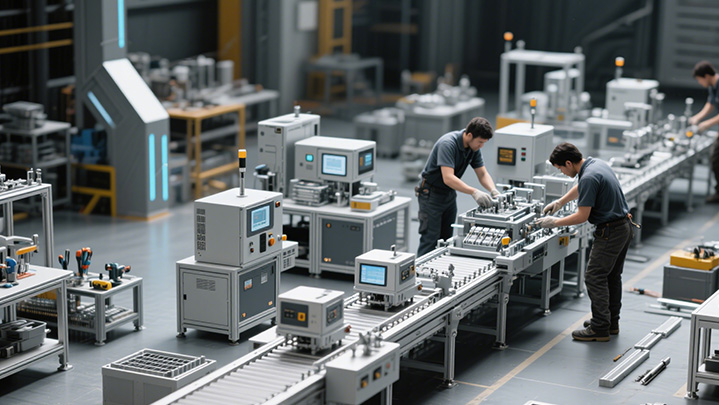

Workstation Layout Simulation (Material / Process / Capacity alignment.)

Ergonomic Optimization (Reduce repetitive strain injury (RSI) risk by 30%.)

Lean Production Roadmap (SMED quick mold change case study.)

Deliverable: Validated production blueprint.

Tier-2 Supplier Audit & Capability Matching (Material / Process / Capacity alignment.)

BOM Cost Tiered Control (Dual-source procurement strategy for Class A components.)

Deliverable: Approved Vendor List (AVL).

Design

DFM

Tooling

Pilot Run

Mass Production

What key stages does your manufacturing engineering service cover?

We support the full product lifecycle from design to mass production, focusing on:

• Design for Manufacturability (DFM):

Optimize product structure (e.g., simplify assembly steps, relax non-critical tolerances) to ensure designs can be efficiently produced with existing processes. Example: Avoid deep blind holes in plastic parts to prevent demolding issues.

• Process Planning:

Develop custom manufacturing routes (e.g., injection molding, CNC machining, stamping), design fixtures and molds, and deliver documents like Process Flow Diagrams and PFMEA Failure Analysis Reports. Example: Create multi-axis machining paths for complex curved components.

• Production Line Design & Layout:

Calculate cycle times (e.g., target ≤ 10 seconds per unit per station), match equipment precision (e.g., CNC machines with ±0.01mm accuracy), and integrate automation (e.g., robotic welding, vision inspection stations) to balance workflow and eliminate bottlenecks.

• Prototype & Mass Production Support:

Monitor trial production to resolve issues like assembly interference or dimensional deviations. Example: Use 3D scanning to compare actual part dimensions with design specs. Deliver Mass Production Process Guides and Quality Control Plans.

• Continuous Improvement:

In mass production, use SPC (Statistical Process Control) and OEE (Overall Equipment Effectiveness) to boost yield (target ≥ 98%) and efficiency. Example: Implement quick die change technology to reduce setup time by 40%.

How do you ensure mass production quality matches the original design?

We use a prevent-detect-improve framework:

• Design Prevention:

Early DFM reviews identify structural flaws (e.g., uneven wall thickness in metal parts causing deformation, weak snap fits) and provide 20+ feasibility recommendations. Example: Suggest a ≥3° draft angle for plastic parts to ease demolding.

• Production Control:

① Error Proofing: Use sensors to detect missing parts and unique fixture定位 pins (only fit correct part orientations) to eliminate human error.

② Full-Procedure Inspection: Conduct first-article inspection (FAI), in-process checks (IPQC), and final-run inspection (FRI) with equipment like CMMs (±0.005mm accuracy) and optical comparators. Test dimensions, geometric tolerances, and surface treatment adhesion (cross-cut test ≥ 4B rating).

• Closed-Loop Improvement:

Document trial production issues (e.g., thread holes failing go/no-go gauges), use 8D reports to identify root causes (e.g., fixture misalignment), update process files, and standardize procedures.

How do you control mass production costs?

We deliver quantifiable cost reduction through three key dimensions:

• Material Costs (Target: 10-20% savings):

① Substitution Optimization: Recommend cost-effective materials without compromising performance. Example: Replace 7075 aluminum with 6061 (25% cost reduction) or use POM instead of PA66 for non-load-bearing parts (30% cost reduction).

① Yield Improvement: Nest cutting for sheet metal (material utilization up from 75% to 85%) and recycle injection molding runner scrap (scrap rate ≤ 5%).

• Process Costs (Target: 15-30% savings):

① Operation Consolidation: Complete drilling, chamfering, and tapping in a single CNC setup (reduces clamping times by 20%). Use multi-cavity molds (e.g., 8-cavity mold cuts per-unit cost by 50% vs. 4-cavity).

② Mold Longevity: Extend mold life from 50,000 to 100,000 cycles via titanium plating and modular design for easy replacement of wear parts.

• Efficiency Costs (Target: 10-30% productivity gain):

① Line Balancing: Apply ECRS principles to optimize workstations. Example: Reduce a bottleneck station from 20 to 12 seconds, increasing line capacity by 40%.

③ Automation: Deploy collaborative robots for repetitive tasks (e.g., screwing, part sorting), saving 2 labor positions per station and reducing annual costs by $15,000.

Do you handle small-batch orders (fewer than 1,000 units)?

Yes! We support 1-1,000-unit orders with flexible solutions:

• Rapid Prototyping:

Deliver 3D-printed/handcrafted samples in 5-7 business days to validate designs. Example: Use SLA technology for complex curved components.

• Trial Production:

Provide 50-200-unit trials with 3 free process adjustments (e.g., mold parting line tweaks, injection parameter optimization), plus a Trial Production Test Report (includes dimensional and performance data).

• Flexible Delivery:

Offer batch production (e.g., 3 batches of 300 units each) and JIT (Just-In-Time) delivery to meet small-order validation needs.

How do you protect intellectual property during manufacturing?

We use a 4-layer security system for confidentiality:

• Legal Protection:

Sign non-disclosure agreements (NDAs) to prohibit disclosure or misuse of drawings, processes, and BOMs, with clear legal and financial consequences for breaches.

• Process Controls:

① Encrypted Access: Store project data in password-protected systems, accessible only to authorized personnel. Paper documents are logged and managed by dedicated staff.

① Dedicated Molds: Label customer molds with unique IDs and store them in secured, isolated warehouses—never repurposed without consent.

• Physical Security:

Isolated Facilities: Use dedicated workshops for sensitive projects with dual-access control (key card + password) and 24/7 surveillance. Unauthorized entry is strictly prohibited.

• Data Privacy:

Split BOM Sharing: Provide partial material/process info to separate suppliers (e.g., Supplier A gets only injection molding details, Supplier B only metal part specs) to prevent full technology exposure."

We use cookies to ensure that we give you the best experience on our website. By clicking "Accept All", you consent to our use of cookies. Learn more.

Please fill out the form and we'll get back to you shortly.

Your submission has been received !

Thank you for your submission.

We will get back to you within 24 hours and appreciate your patience.

Enter your details to receive the toolkit for free.