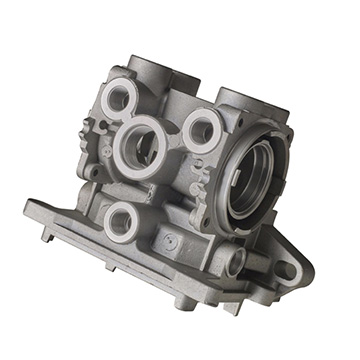

Die Casting

Precision Die Casting Manufacturing, Honoring Classic Craftsmanship

Die casting utilizes high-pressure injection of molten metals (aluminum/zinc alloys) into steel molds, enabling mass production of precision components with complex geometries.Delivering dimensional stability and superior surface finish , it minimizes post-processing.