CNC Machining

Accelerating innovation from aerospace to medical.

Precision CNC machining services for complex parts, serving automotive, aerospace, and medical industries with automated control and multi-material compatibility.

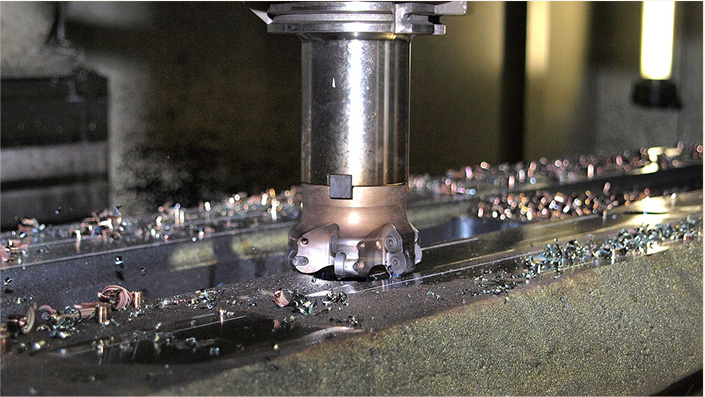

Delivering 3-5 axis simultaneous milling solutions for complex cavities, contoured surfaces, and precision components. Compatible with stainless steel, titanium alloys, engineering plastics, etc., achieving ±0.005mm tolerances for both rapid prototyping and volume production.

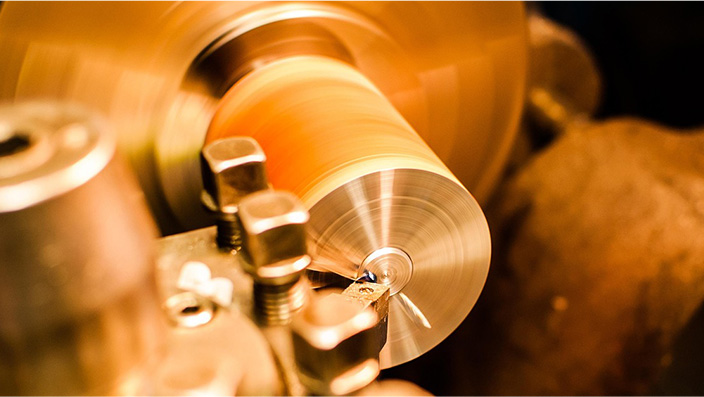

Specialized in precision shaft and disc components with integrated turning-milling capabilities. Equipped with dual spindles and live tooling to complete OD/ID machining, threading, and grooving in single setup, enhancing productivity by 30%+.

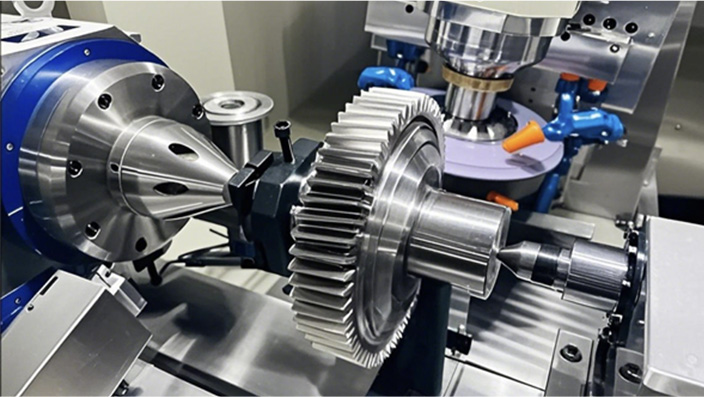

Custom gear manufacturing for spur, helical, and worm gears with module range 0.5-10 and DIN Class 5 accuracy. Integrated gear profile modification and heat treatment processes ensure reliability for high-load applications like robotics and automotive transmissions.

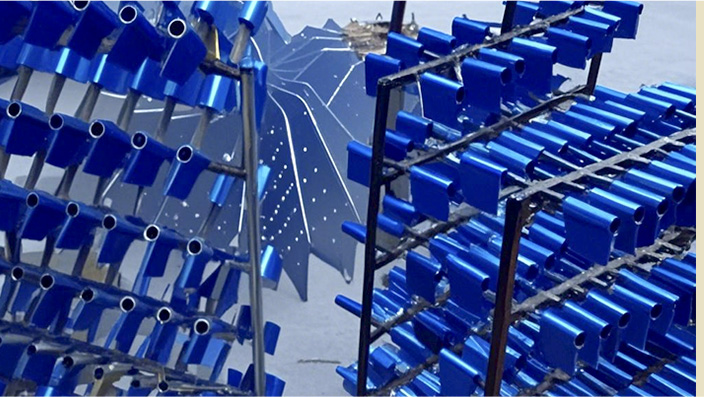

Painting: Electrostatic powder coating (60-120μm, ≥500h salt spray)、Auto-paint line (≤5min color change)

Plating/Anodizing: Zinc plating (8-12μm, ≥720h NSS)、Anodizing (Al, 10-25μm, ≥1000x abrasion resistance)

Other Finishes: Brushing/sandblasting (Ra0.4-3.2μm)、Laser etching (±0.05mm accuracy, 0.1-0.5mm depth)

Material Traceability | Full inspection & documentation for raw materials with traceability

Process Control | FAL checkpoints with IPQC real-time monitoring throughout production

Warehouse Re-inspection | Dual quality verification + phase QC reports

Shipping Assurance | Final inspection with COC/COA certification

Equipment Maintenance | Periodic calibration of machining tools

We use cookies to ensure that we give you the best experience on our website. By clicking "Accept All", you consent to our use of cookies. Learn more.

Please fill out the form and we'll get back to you shortly.

Your submission has been received !

Thank you for your submission.

We will get back to you within 24 hours and appreciate your patience.

Enter your details to receive the toolkit for free.