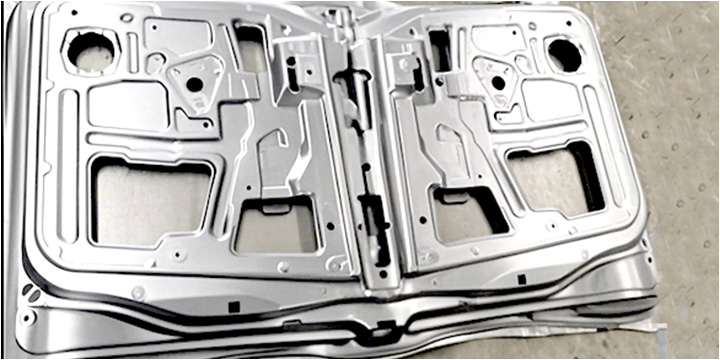

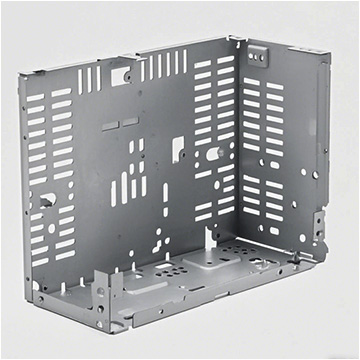

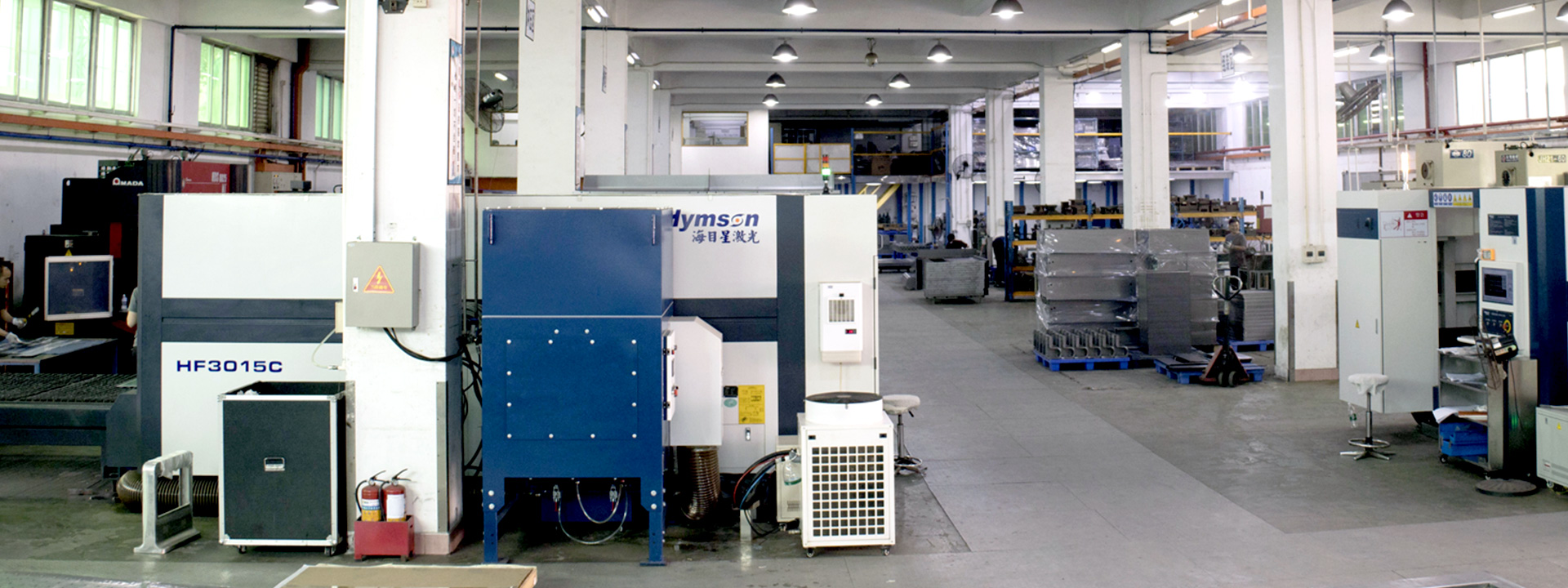

Sheet Metal Fabrication

Precision Metal Forming Solutions

Laser cutting (12kw), CNC bending (±0.05mm), TIG/MIG welding, and surface finishing (spray coating/anodizing) for 0.5-12mm stainless steel, aluminum, and galvanized steel. ISO 9001 & IATF 16949 certified, serving new energy, telecom, and medical sectors with 24h prototyping.