An inertial motion capture system designed and developed for FOHEART

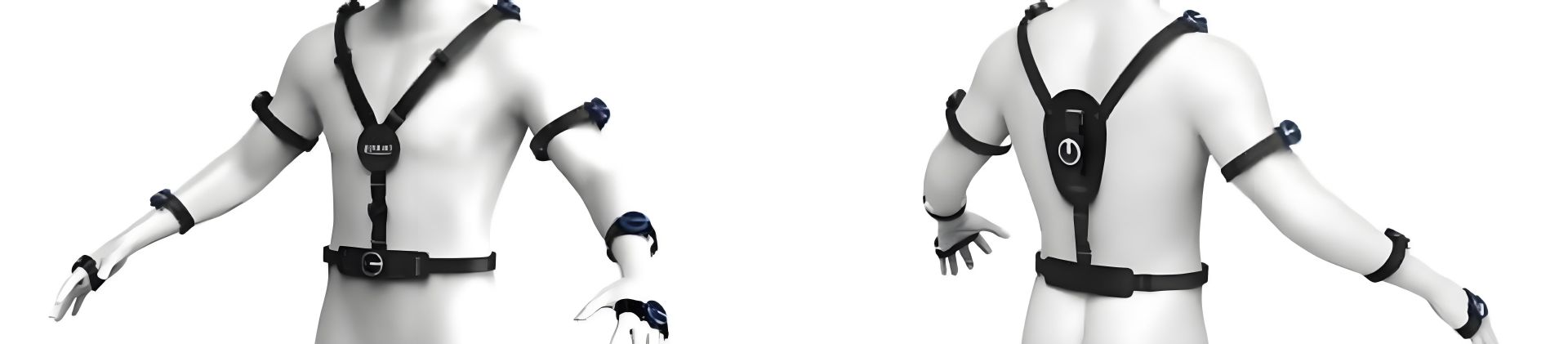

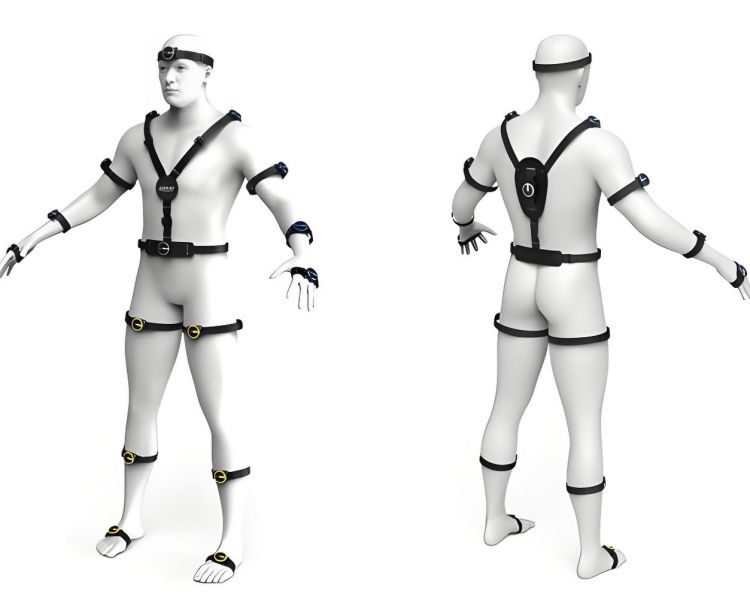

The FOHEART C1 is a high-precision, low-latency, and low-power inertial motion capture system developed based on MEMS inertial sensors. Utilizing a network of 17 wireless nodes distributed across the body, each integrating a nine-axis gyroscope, accelerometer, and magnetometer sensor array, the system accurately captures intricate human movement data. The client aimed to develop a product that combined ergonomic functionality with exceptional aesthetic appeal to drive the advancement of VR technology and meet the high standards of both industry professionals and consumers. LKK Design was entrusted with the comprehensive product design, encompassing the appearance and structural design of the inertial capture modules, charging case, and wireless router.

The client's core requirements for the product were:

Achieve a lightweight and highly reliable design, ensuring the product fits the human body comfortably and improves data capture accuracy.

The structural design had to balance thermal management with antenna layout, adhering to a flat, minimalist aesthetic language.

The node design needed to embody the "Starry Sky" concept, using blue, yellow, and dark gray colors to differentiate wearing positions, thereby enhancing visual hierarchy and wearability.

1. Design Research

During the initial phase, our team conducted in-depth research into ergonomics, motion capture technology, and user scenarios. By analyzing the relationship between sensor placement and human biomechanics, we defined key parameters for node distribution, size, and form, ensuring optimal performance alongside comfort for prolonged use.

2. Industrial Design

Guided by the "Starry Sky" design philosophy, we developed small, lightweight circular nodes. Color-coding different functional zones enhanced visual distinction and aesthetic appeal. The overall design employs a flat, minimalist language, making the product compact, form-fitting, and imbued with a sense of technological sophistication.

3. Mechanical Structure Design

Node and Charging Case Structure: Utilizing lightweight materials and high-precision engineering, we ensured node stability and reliability during dynamic movement. The charging case was designed for portability and convenient storage of all nodes.

Router Structure: We innovatively integrated the heat vent layout with the antenna mechanism. This solution effectively dissipates heat while maintaining a clean, flat exterior, achieving a perfect balance between aesthetics and functionality.

4. Electronic Design

For the electronic design, we focused on optimizing power management and signal stability across the 17 wireless nodes. Through meticulous circuit board layout, we achieved efficient integration of the nine-axis sensors within the confined space, ensuring low-latency data transmission and high reliability. Additionally, we developed a dedicated antenna system and power management module for the router, guaranteeing stable wireless communication and effective overall power consumption control.

5. Prototyping and Testing

Through rapid prototyping, we conducted multiple iterative tests on node comfort, router thermal performance, and signal stability. Feedback from these tests led to refinements in the node's contact surface curvature and the router's vent size and distribution, ensuring each component met our rigorous design standards.

6. Mold Development and Mass Production

During the mold development phase, we employed high-precision mold manufacturing to ensure part consistency and ease of assembly. A strict quality control process throughout manufacturing guaranteed a high-quality transition from prototype to mass production.

LKK Design delivered a complete product development solution for the FOHEART C1, from initial concept and structure to prototyping and mass production. Since its launch, the product has garnered significant attention from the industry and consumers alike, praised for its sleek design and precise motion capture capabilities, substantially contributing to the practical application of VR technology. The client expressed great satisfaction with LKK Design's professional service and successful outcomes. This collaboration further solidifies our leading position in the smart wearable device design sector.

We use cookies to ensure that we give you the best experience on our website. By clicking "Accept All", you consent to our use of cookies. Learn more.

Please fill out the form and we'll get back to you shortly.

Enter your details to receive the toolkit for free.