Tooling Manufacturing

Precision Tooling Solutions for Mass Production Excellence

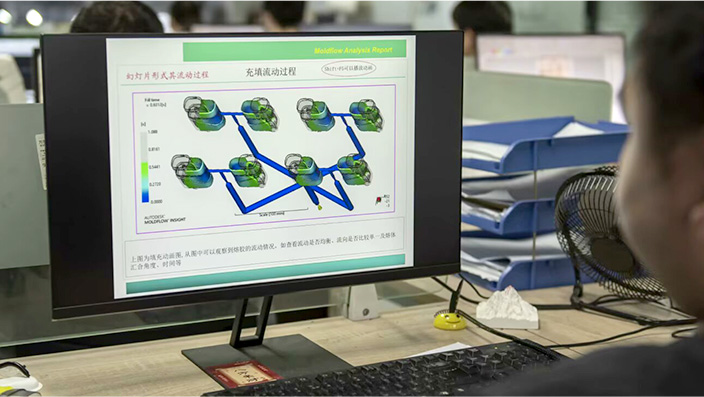

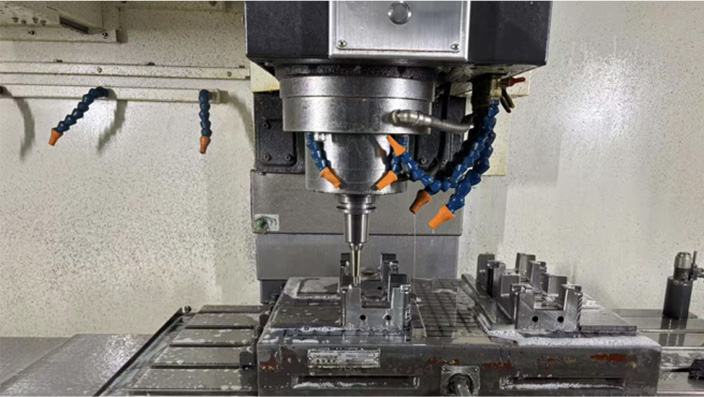

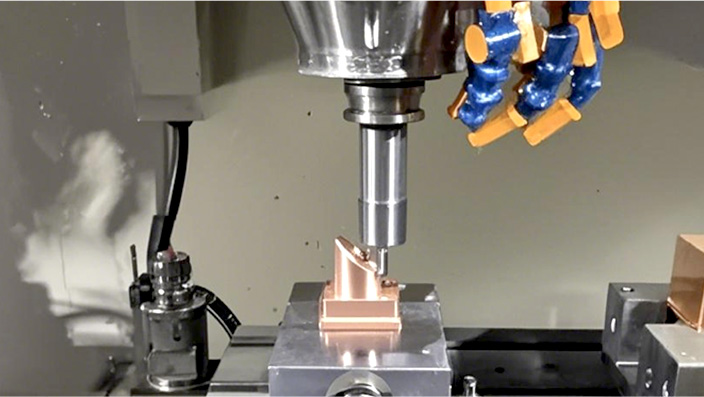

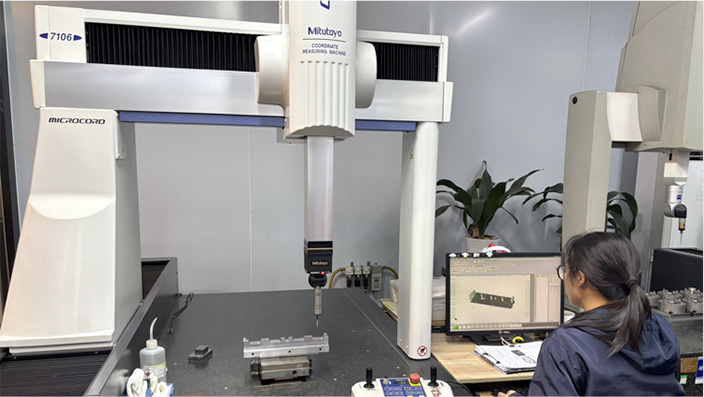

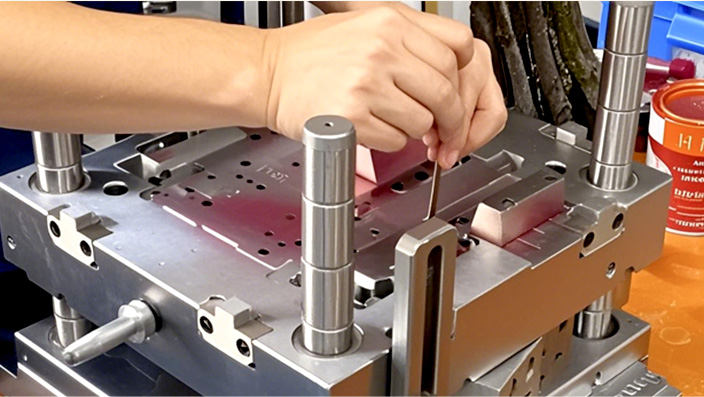

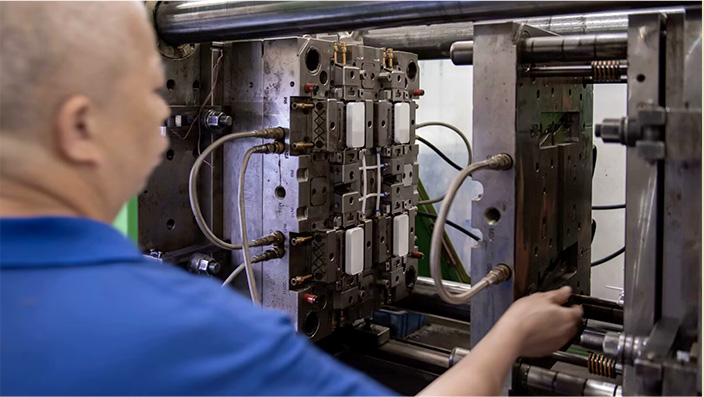

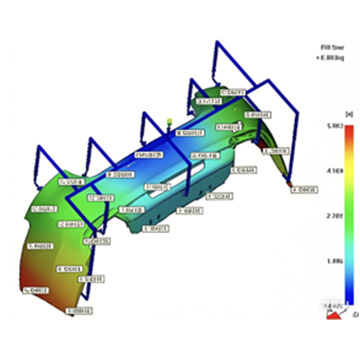

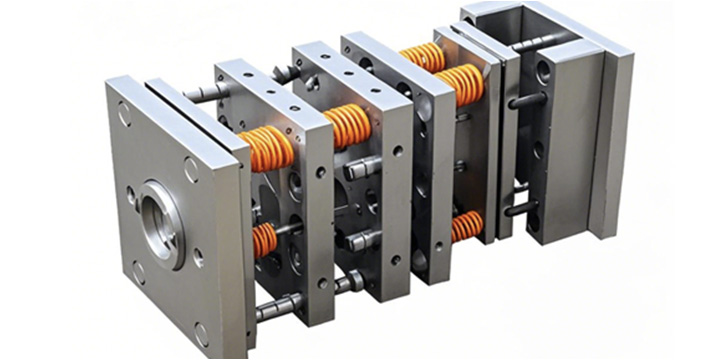

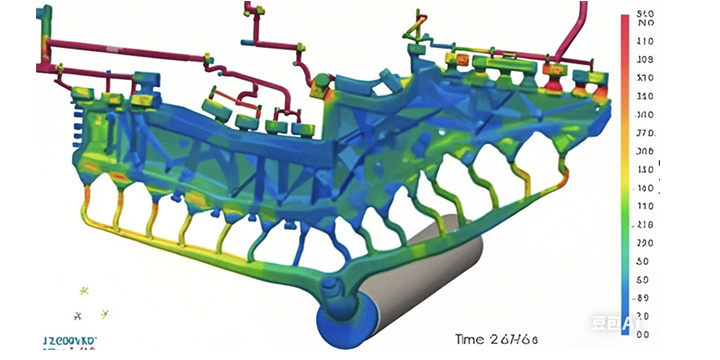

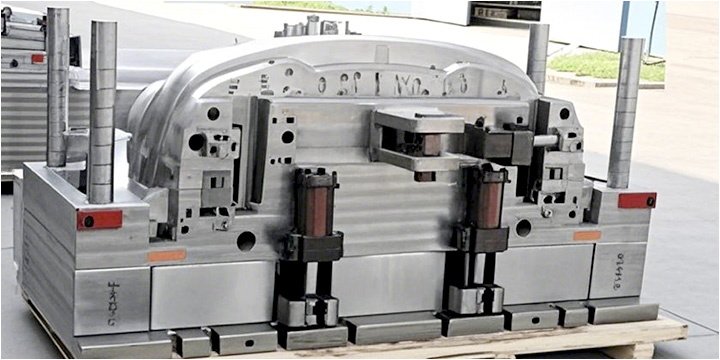

Tooling solutions include injection/die-casting/stamping mold design and manufacturing. Using S136 tool steel and hot runner systems, we achieve ±0.02mm accuracy and 100,000+ cycles. Accelerate pilot runs for automotive, electronics, and medical components.