Lkk develops Ceribell AI EEG products to create a new chapter in medical technology

Product introduction

Ceribell AI EEG is a portable, cutting-edge brain wave monitoring device designed for on-site medical care. By integrating the latest advancements in neuroscience and engineering, it delivers instant and precise brain wave data. The device uses advanced AI algorithms to analyze the data, providing initial diagnostic insights and support to doctors and nurses during treatment. Ceribell AI EEG is compact, lightweight, and user-friendly, making it perfect for emergency rooms, intensive care units, and patients' bedsides.

Demand mining and product definition

The Ceribell team took a closer look at their need for a portable brainwave monitoring device. Through multiple meetings and discussions, we have clarified the product's core functions, target users, and market positioning. We emphasized the importance of integrating AI technology.

Technology R&D and innovation

In order to meet the high standards of the product and incorporate AI technology, Ceribell has integrated technical resources and organized a dedicated team of neuroscientists, engineers, technologists and AI algorithm engineers. After several rounds of technical discussions and experiments, we developed a highly portable, accurate, and real-time EEG monitoring technology. We integrated advanced AI algorithms to automatically analyze EEG data and provide preliminary diagnostic recommendations.

Material supplier development challenges

In the product development process, supplier selection and material quality are key to ensuring the performance of the final product. Especially for the elastic textile materials used in headwear, these materials must meet FDA certification standards. During the development stage, the lack of stable large orders made finding suppliers challenging. After relentless efforts, the LKK team found a supplier that met the requirements and established a long-term relationship with them.

For the electrode wire, due to the high sensitivity of EEG monitoring, there are strict standards for the impedance of the electrode wire. The LKK team searched across China, conducted numerous tests, and finally found a supplier that met the standards. This ensured the performance and quality of the product.

In addition, the packaging of conductive gels is also a huge challenge. The gel is non-solid and must be installed as a consumable inside the product after packaging, requiring extremely precise sizing. We ensured the dimensional accuracy and stability of the gel package while controlling costs to meet market demand. After many trials and optimizations, we successfully overcame this challenge.

Quality control - zero defect pursuit

In the process of product development, quality control is very important. Since the consumables are disposable and cannot be fully inspected, we must ensure zero defects in the production process. To achieve this, we have implemented a strict quality management system to carefully monitor every step.

Especially for the impedance and oxidation problems of the electrode wire, we have taken a number of measures to ensure its stability and reliability. We also perform precise measurements and controls to ensure the dimensional accuracy of the gel, meeting the highest standards for every product.

Achievements of the product

Since the advent of Ceribell AI EEG, it has achieved remarkable success on a global scale. In several hospitals, the product has helped doctors diagnose epilepsy, brain injuries, and other neurological disorders accurately, providing critical information for timely treatment. Its portability and real-time performance enable medical personnel to quickly obtain patients' brainwave data and provide timely, effective care.

More importantly, by integrating AI technology, Ceribell AI EEG is able to provide initial diagnostic recommendations, providing a powerful auxiliary tool for physicians. This intelligent function improves diagnostic accuracy and efficiency, reduces doctors' workload, and allows them to focus more on treating and caring for patients.

In addition, Ceribell AI EEG has been recognized with several international certifications and awards, demonstrating its leading position in the field of brainwave monitoring. These achievements highlight the technical strength of our Lkk team and exemplify Ceribell's innovative spirit.

Together, the collaboration between Lkk and Ceribell brings revolutionary innovation to the field of healthcare. By integrating AI technology, we have developed a portable brain wave monitoring device with intelligent features, contributing to the global health cause. In the future, we will continue to work together to bring more innovations and breakthroughs in the field of healthcare.

In the end, with the remarkable success of this product, Ceribell has not only become famous in the field of EEG, but also become a shining star in the industry, and its innovative technology and excellent results have won widespread praise in the industry. On October 12, 2024, Ceribell successfully listed on the NASDAQ Stock Exchange, marking a significant milestone in its development. This achievement highlights a brighter future and endless possibilities.

Others Cases

-

Smart Aquatics Feeding Machine

Innovative solutions for modern aquaculture industry

-

Home Vegetable Planter

The perfect combination of technology and green

-

Hongdu Weeder

LKK Design helps Jiangxi Hongdu Weeder product design and development

-

Innovative Dog Harness

We are not able to show more product images or disclose the names of our clients...

-

Smart Car Sunshade

We are not able to show more product images or disclose the names of our clients...

-

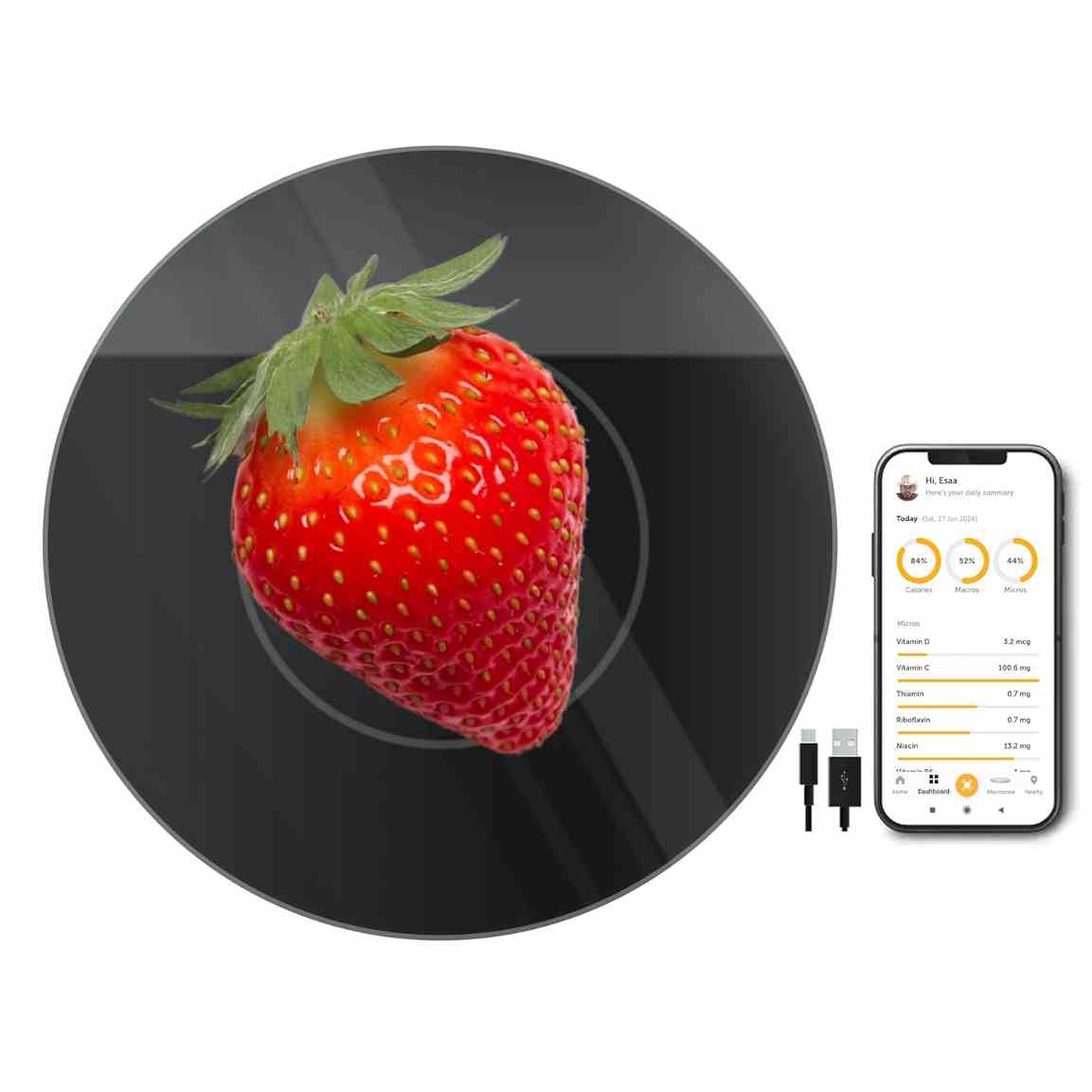

Smart(IOT) food scale

Product design and development of smart Bluetooth kitchen food scale

Latest

October 2024

LKK and HHOGene launch world's first light-controlled TWS earbuds

News May 2025

LKK Design & SAB Saudi Host Vision 2030 Seminar

Technical May 2025

US-China tariff truce leads to restart of needle-free injection device project by LLK Design

Technical April 2025

LKK Design Wins 8 Red Dot Awards in 2025

Technical March 2025