Project Background

In the ever-evolving landscape of educational technology, finding innovative tools that ignite children's curiosity and foster critical skills has become paramount. TTS Group, a renowned UK-based educational products provider, approached LKK Design with a vision to create an all-in-one solution that revolutionizes the way children learn about programming and robotics. The goal was to design Oti-Bot, a child-friendly robot that not only simplifies coding but also integrates AI, creativity, and hands-on learning experiences into the classroom.

Solution: Introducing Oti-Bot

Oti-Bot, conceived as a collaborative effort between LKK Design and TTS Group, embodies the future of computing education. This revolutionary tool combines programmable caterpillar tracks, a line follower, a color sensor, and direct internal storage capabilities, enabling students to document their work and progress seamlessly. At its core, Oti-Bot fosters computational thinking, problem-solving, and logical reasoning skills, directly supporting the UK Computing Curriculum at Key Stages 1 and 2.

Project Flow

1. Industrial Design

LKK Design kicked off the project by immersing themselves in user research, studying the needs and preferences of both children and educators. Based on insights gathered, the team crafted an aesthetically pleasing and child-friendly design that incorporates playful elements while maintaining a professional and educational appearance. The robot's interchangeable tummies, each designed for a different learning activity, added a layer of versatility and engagement.

2. Mechanical Design

The mechanical design phase focused on creating a sturdy yet agile frame that could withstand the rigors of classroom use while enabling smooth movements and interactions. Special attention was given to the caterpillar tracks, ensuring they could navigate various surfaces and enhance the robot's maneuverability.

3. Hardware Development

The hardware development team sourced high-quality components for the color sensor, camera, and motor systems, ensuring reliability and precision. Integrating these components into the robot's compact body required meticulous engineering and careful placement to maintain balance and functionality.

4. Firmware Development

The firmware was designed to be updatable, allowing Oti-Bot to stay current with technological advancements. It also facilitated seamless communication between hardware components, ensuring smooth operation and responsiveness.

5. Software Development

A user-friendly block-based programming environment was developed, accessible via a free app, making coding accessible and enjoyable for children of all skill levels. The app also allowed for live streaming and AI-powered face recognition, enhancing the interactivity and engagement between students and Oti-Bot.

6. Prototype Making & Testing

Multiple prototypes were created and rigorously tested for durability, functionality, and user experience. Feedback from educators and children was incorporated into iterative designs, refining Oti-Bot until it met all expectations.

7. Mold Development

With the final design approved, LKK Design collaborated with manufacturing partners to develop injection molds for mass production. This process ensured the quality and consistency of each Oti-Bot unit.

8. Certification

To ensure safety and compliance with international standards, Oti-Bot underwent rigorous safety testing and obtained the necessary certifications, including CE marking for the European market.

9. Pilot Production

A small-scale production run was conducted to validate the manufacturing process and assess quality control measures. This step helped identify and address any potential issues before mass production.

10. Mass Production

With all preparations in place, Oti-Bot entered mass production, ready to be distributed to schools and educational institutions across the UK and beyond.

Value Proposition

Oti-Bot represents a significant leap forward in computing education, offering a comprehensive platform that integrates coding, robotics, AI, and creativity into one engaging package. By supporting the UK Computing Curriculum and fostering critical 21st-century skills, Oti-Bot prepares children for a future where technology is an integral part of everyday life. The collaboration between LKK Design and TTS Group demonstrates the power of innovation and dedication to creating tools that inspire and educate the next generation of digital natives.

We provide one-stop product development services:industrial design, mechanical design,Electronic Design(Hardware), firmware design,rapid prototyping,small batch production,DFM,Mold design and manufacturing, Validation&Certification, mass production, etc

Others Cases

-

Smart Aquatics Feeding Machine

Innovative solutions for modern aquaculture industry

-

Home Vegetable Planter

The perfect combination of technology and green

-

Hongdu Weeder

LKK Design helps Jiangxi Hongdu Weeder product design and development

-

Innovative Dog Harness

We are not able to show more product images or disclose the names of our clients...

-

Smart Car Sunshade

We are not able to show more product images or disclose the names of our clients...

-

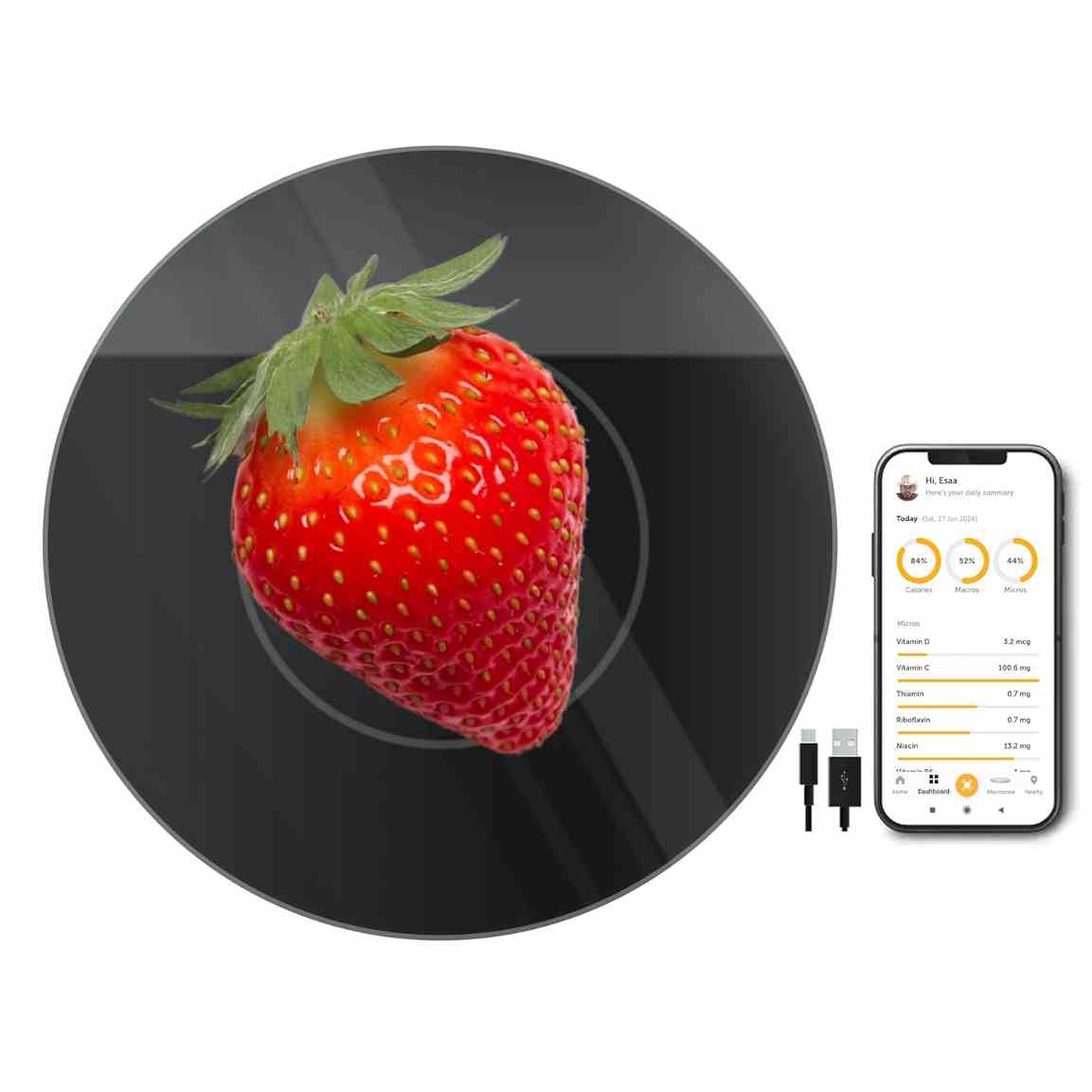

Smart(IOT) food scale

Product design and development of smart Bluetooth kitchen food scale

Latest

October 2024

LKK and HHOGene launch world's first light-controlled TWS earbuds

News May 2025

LKK Design & SAB Saudi Host Vision 2030 Seminar

Technical May 2025

US-China tariff truce leads to restart of needle-free injection device project by LLK Design

Technical April 2025

LKK Design Wins 8 Red Dot Awards in 2025

Technical March 2025