Prototyping

Precision Prototype Manufacturing, Accelerating Design-to-Production

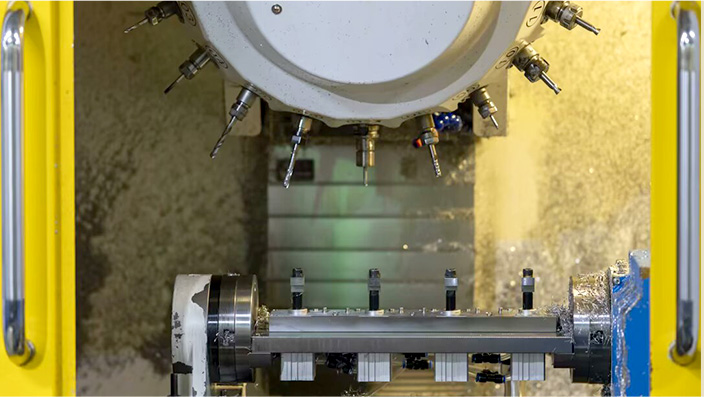

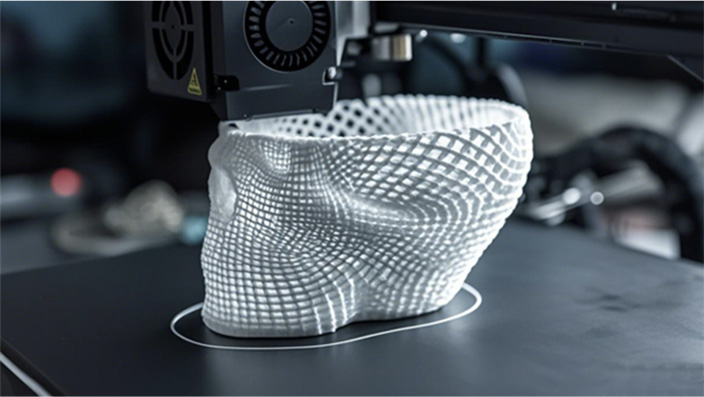

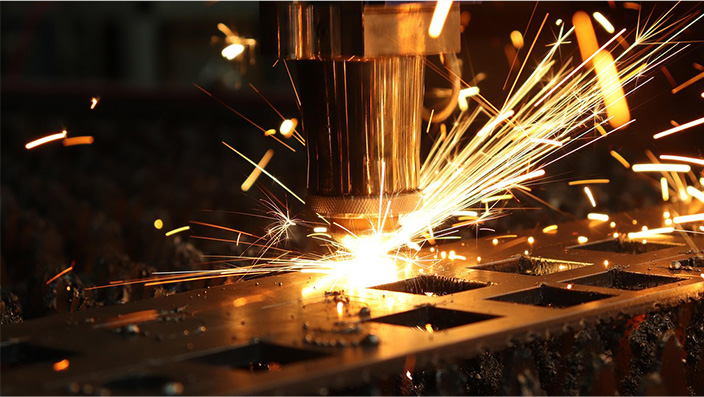

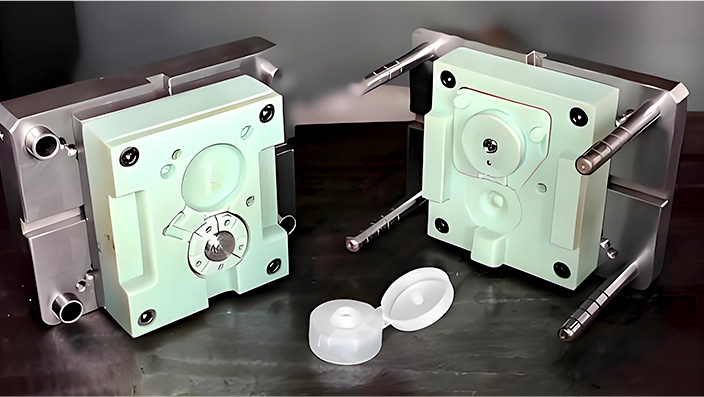

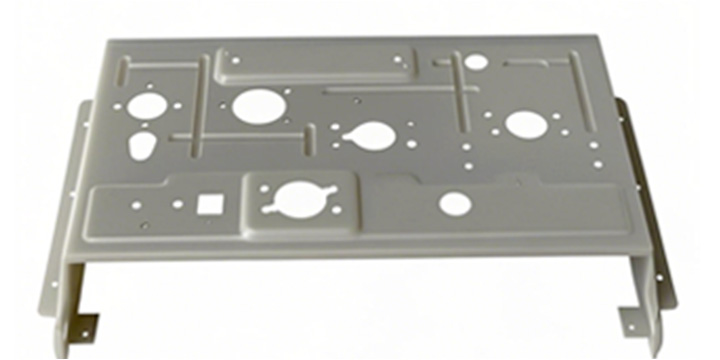

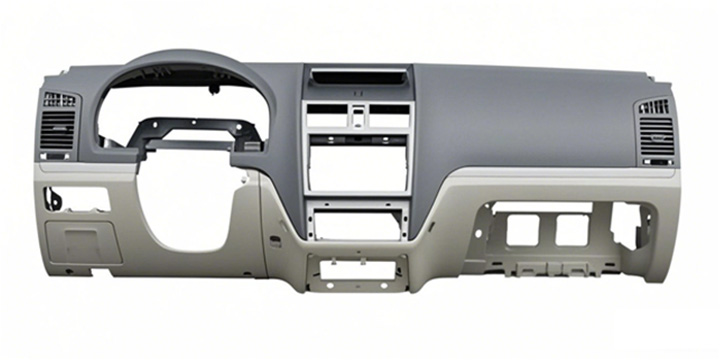

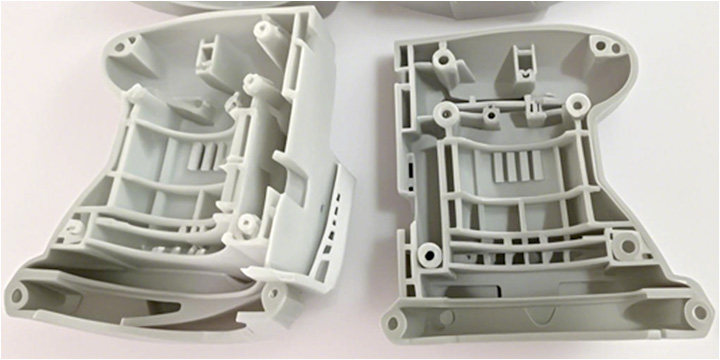

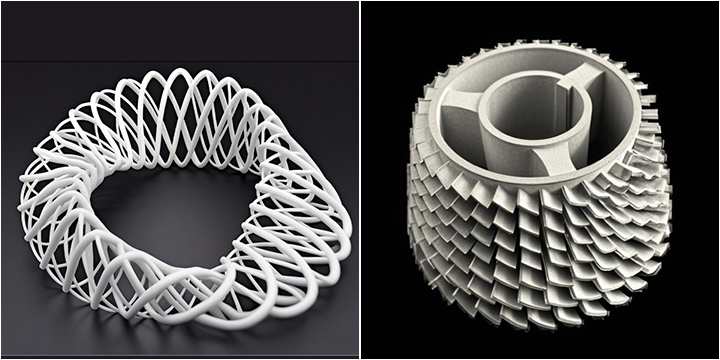

Rapid prototyping (3D printing/CNC/vacuum casting) delivers precision models (±0.1mm) within 24-72hrs, accelerating development cycles for electronics, automotive, and medical products while mitigating 80% R&D risks.