Rapid sheet metal prototyping is a set of rapid prototyping services for the production of sheet metal parts. This includes various forming, cutting, and assembly processes for manipulating the sheet metal stock in different ways.

Rapid sheet metal prototyping is generally used for flat parts like brackets and enclosures, and it can accommodate a range of sizes, including very large metal parts. Setup times can be longer than comparable processes, but sheet metal is highly cost-effective when making large and relatively simple parts.

An advantage of rapid sheet metal prototyping is that the solid sheet metal feedstock can later be CNC machined for additional features.

Process for the Sheet Metal Fabrication Services:

Laser Cutting-Punching-sheet metal forming-Welding-Grinding-Finishing-Assembly-Machining if need

Which materials can Grenville Engineering fabricate?

- Stainless Steel

- Steel

- Aluminum

How Can LKKER SCM Help?

In addition to our skilled team, LKKER SCM engineers strive to offer a fantastic service. We understand the exact needs of metal fabrication, so we built up a reputation for ensuring we produce exact parts to meet your expectations.We have a wide range of experience and knowledge in the metalworking sector, which we are happy to share with you. If you are not sure what you need, tell us your current specifications and we can narrow down your search by materials, fabrication method, and more.

Other Services

Industrial Design Services

-

Supplier Matching Service

-

Project Management

-

Certification

-

DFM Design for Manufacturing

-

Mechanical Design Services

-

Electronic Design Services

Develop product hardware and card software; standardize hardware development processes; control hard...

-

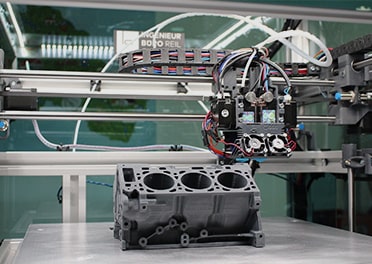

Rapid Prototyping China

Rapid prototype For Consumer Electronics. Get your free, instant quote.

-

Injection Molding Service

-

Small Batch Production

-

Packaging Design Services

-

Mass Production

Latest

October 2024

LKK and HHOGene launch world's first light-controlled TWS earbuds

News May 2025

LKK Design & SAB Saudi Host Vision 2030 Seminar

Technical May 2025

US-China tariff truce leads to restart of needle-free injection device project by LLK Design

Technical April 2025

LKK Design Wins 8 Red Dot Awards in 2025

Technical March 2025