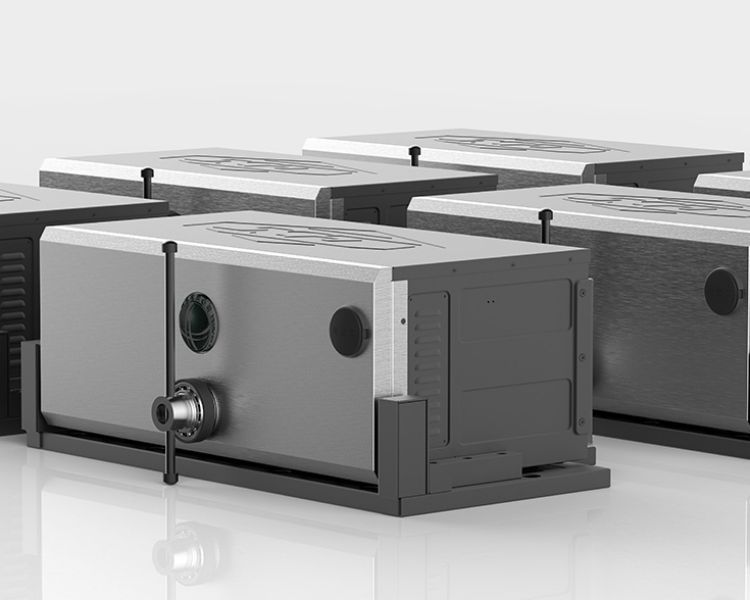

A bus battery box designed for XJ Group, a subsidiary of State Grid Corporation of China

In the global shift towards sustainable energy and carbon neutrality, green public transportation is more critical than ever. LKK Design was proud to collaborate with XJ Group, a core subsidiary of State Grid Corporation of China, to develop a next-generation, standardized Bus Battery Box. Leveraging our expertise in design and engineering, we delivered a solution that facilitates the large-scale adoption of electric buses.

Client: XJ Group Corporation

A leading enterprise in China's power equipment industry and a comprehensive power equipment manufacturer under State Grid. XJ Group's product portfolio spans power generation, transmission, distribution, and consumption. This project was a strategic initiative to advance their footprint in green mobility.

Project: Bus Battery Box Design & Engineering

The mission was to create a Bus Battery Box for fully automated, robotic battery swapping stations. The core objectives were to ensure the product was easy for robots to install, simple for human maintenance, and featured a secure and reliable locking mechanism. This was not just a product design task but a crucial step towards standardizing and optimizing bus battery replacement.

The project focused on overcoming key challenges in automated battery swapping: precision positioning, reliable locking, and efficient serviceability. Our key design goals were:

High-Precision Docking: Compensate for manufacturing tolerances to ensure a secure fit within the battery rack with no play, guaranteeing the mechanism operates at its dead point for absolute stability.

Low-Torque Operation: Minimize the torque required for the robotic locking mechanism to ensure smooth operation, reduce energy consumption, and enhance component longevity.

Serviceability and Aesthetics: Design components like cooling fans to be functional, cost-effective to produce, and visually coherent.

Optimized Structure: Implement a low-profile tray-style battery rack design, providing a solid foundation for lock sleeves and guide wheels.

LKK Design assembled a cross-disciplinary team, following a systematic process to transform client requirements into a robust, engineered solution.

1. Design Research

We conducted an in-depth analysis of the swapping station workflow, robotic operational parameters, and maintenance routines. By identifying potential interference points, wear points, and service pain points, we prioritized reliability, usability, and cost-effectiveness.

2. Industrial Design

Our aesthetic approach prioritized a clean, robust, and professional appearance. We championed form following function. For instance, the fan outlet features a simple round hole pattern. As the fan includes its own filter, this design maintains a unified look while significantly reducing tooling and manufacturing complexity.

3. Mechanical Structure Design

This was the core of our innovative engineering effort:

Elastic Compensation Locking Mechanism: To address precision alignment, we innovated by adding a layer of elastic gum between the locking plate and sleeve. This allows for slight tolerance compensation during engagement but provides a rigid, near-dead-point lock when under load.

Low-Torque Rotation System: To minimize robotic operational torque, we designed the contact surface of the locking plate as a curved arc, reducing friction. Furthermore, we incorporated a bearing on the rotating colonnette, secured via an interference fit or snap ring, ensuring exceptionally smooth rotation.

Tray-Style Battery Rack: We optimized the rack into a low-profile tray configuration. The left and right lock sleeves and guide wheels are mounted directly onto the robust underlying square steel, creating a stable, low-center-of-gravity structure ideal for robotic access and positioning.

4. Prototyping and Testing

Upon finalizing the design, we moved swiftly to prototype manufacturing and assembly. In a simulated real-world testing environment, we rigorously evaluated the Bus Battery Box for locking/unlocking cycles, vibration resistance, long-term load performance, and successful docking under misaligned conditions. The tests confirmed the effectiveness of the elastic gum solution, and the bearing system successfully reduced operational torque to the target level, meeting or exceeding all key performance indicators.

The successful collaboration between LKK Design and XJ Group resulted in a Bus Battery Box that delivers tangible value:

Standardization and Scalability: The standardized design allows the Bus Battery Box to be adapted across various electric bus models, paving the way for widespread adoption.

Intelligent, Unmanned Swapping: Integrated with high-speed machine vision and automated servo tracking, the system enables simultaneous multi-box replacement. It supports centralized local and remote control, enabling unmanned swapping stations that reduce staffing needs and boost operational efficiency and safety.

Innovative Business Model: The product enables a "battery-as-a-service" lease model, separating the vehicle from the battery to lower initial purchase costs and accelerate electric vehicle adoption.

Significant Social Benefits: Centralized battery management and the potential for secondary life use extend the battery's lifecycle, supporting a circular economy and contributing to urban emission reduction goals.

This project exemplifies LKK Design's user-centric, technology-driven philosophy. We are not just stylists but end-to-end solution providers, dedicated to empowering industries through design and co-creating a more sustainable future.

We use cookies to ensure that we give you the best experience on our website. By clicking "Accept All", you consent to our use of cookies. Learn more.

Please fill out the form and we'll get back to you shortly.

Your submission has been received !

Thank you for your submission.

We will get back to you within 24 hours and appreciate your patience.

Enter your details to receive the toolkit for free.