We are A 18 Year’s Old Innovative Industrial Design Company And We Are The Largest Design Company In China.We provide one-stop product development services, including industrial design, mechanical design, Electronic Design(Hardware), firmware design, rapid prototyping,small batch production,DFM,Mold design and manufacturing, Validation&Certification, mass production, etc

EMBEDDED ELECTRONIC DESIGN FOR MANUFACTURING IN CHINA

Titoma’s electronic engineers have been designing and manufacturing electronic products in China since 2004. We have the in-house skills and experience to develop Embedded Solutions, Connected IoT Devices and Industrial Equipment.

EMBEDDED SOLUTIONS FOR HARDWARE

Our in-house teams of electronic engineers develop products based on embedded solutions

WIRELESS CONNECTED IOT DEVICES

We have a wealth of experience designing wirelessly connected devices and Internet Of Things (IOT) products based on wireless protocols such as: RFID, Bluetooth (BT), Bluetooth Low Energy (BLE), WiFi, LoRa etc.

INDUSTRIAL EQUIPMENT

Reliability is a top concern for all the products we design, but nowhere is this as important as with industrial equipment. We have done a lot of work with UV curing devices and RFID access control.

USER INTERFACE DESIGN

We have experience with user interface design such as the control of LCD’s, buttons with just the right feel and click.

FCC & CE CERTIFICATIONS

When engineering our electronic embedded devices we always keep EMI & EMC Compliance in mind, and work closely with the local RF test labs to assure speedy certification.

REAL TIME COOPERATION WITH ELECTRONIC COMPONENT VENDORS

China manufacture a wealth of very competitive electronic components and modules, but the English documentation for these is often lacking. Having all possible vendors within an hour drive of our office ensures a level of support that most electronic design firms in the West can only dream of.

LKKER SCM provides design for manufacturing service. Contact Us NOW >>> Follow LKKER SCM Linkedin Company Updates>>>

We make sure you have the right product design for rapid, quality and cost effective manufacturing and take advantage of the supply chain resources in China safely.

Other Services

Industrial Design Services

-

Supplier Matching Service

-

Project Management

-

Certification

-

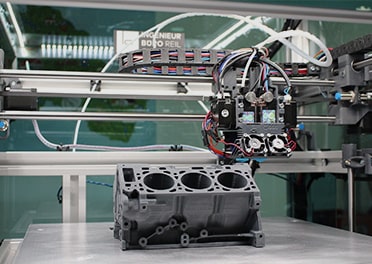

Rapid Prototyping China

Rapid prototype For Consumer Electronics. Get your free, instant quote.

-

Injection Molding Service

-

Small Batch Production

-

DFM Design for Manufacturing

-

Mechanical Design Services

-

Electronic Design Services

Develop product hardware and card software; standardize hardware development processes; control hard...

-

Packaging Design Services

-

Mass Production

Latest

October 2024

LKK and HHOGene launch world's first light-controlled TWS earbuds

News May 2025

LKK Design & SAB Saudi Host Vision 2030 Seminar

Technical May 2025

US-China tariff truce leads to restart of needle-free injection device project by LLK Design

Technical April 2025

LKK Design Wins 8 Red Dot Awards in 2025

Technical March 2025