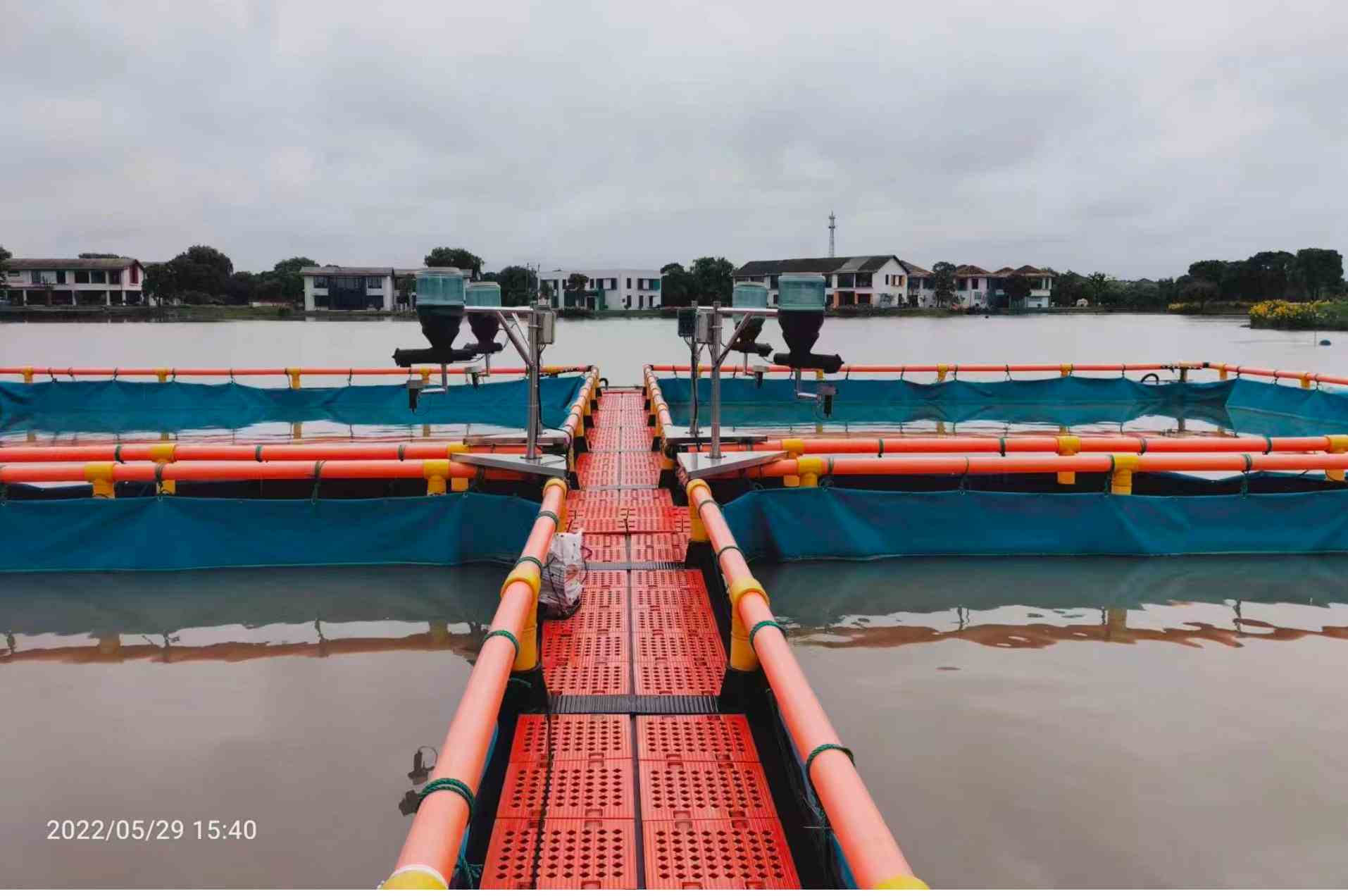

Project background:

With the improvement of people’s awareness of food safety and environmental protection, modern aquaculture industry is facing more and more challenges. The traditional feeding method has some problems, such as low efficiency, waste of food, and lack of effective monitoring and management means, which can not achieve accurate feeding. In order to solve these problems, Dalian Smart Fishery Technology Co., Ltd. decided to develop an intelligent feeding machine to improve feeding efficiency, reduce operating costs, and ensure the quality of farmed fish.

Product design:

After receiving the project, the LKK Design team first conducted in-depth market research to fully understand the needs of users and the characteristics of the farming environment. We found that farmers needed an efficient, intelligent and easy-to-operate device that could respond flexibly in different farming environments. Therefore, we decided to design an intelligent feed machine with the following characteristics:

Can be replaced with different dumping tray to adapt to different specifications of bait;

Adjustable casting distance makes the food distribution more uniform;

The equipment runs stably, the working current is stable, and the long-term stable operation of the equipment is guaranteed.

The equipment power is moderate to meet the needs of efficient feeding;

Feeding specifications can be adjusted to adapt to different sizes of farmed fish;

Feeding speed can be adjusted to achieve accurate feeding;

Special connection structure, so that the tray can be quickly disassembled and washed;

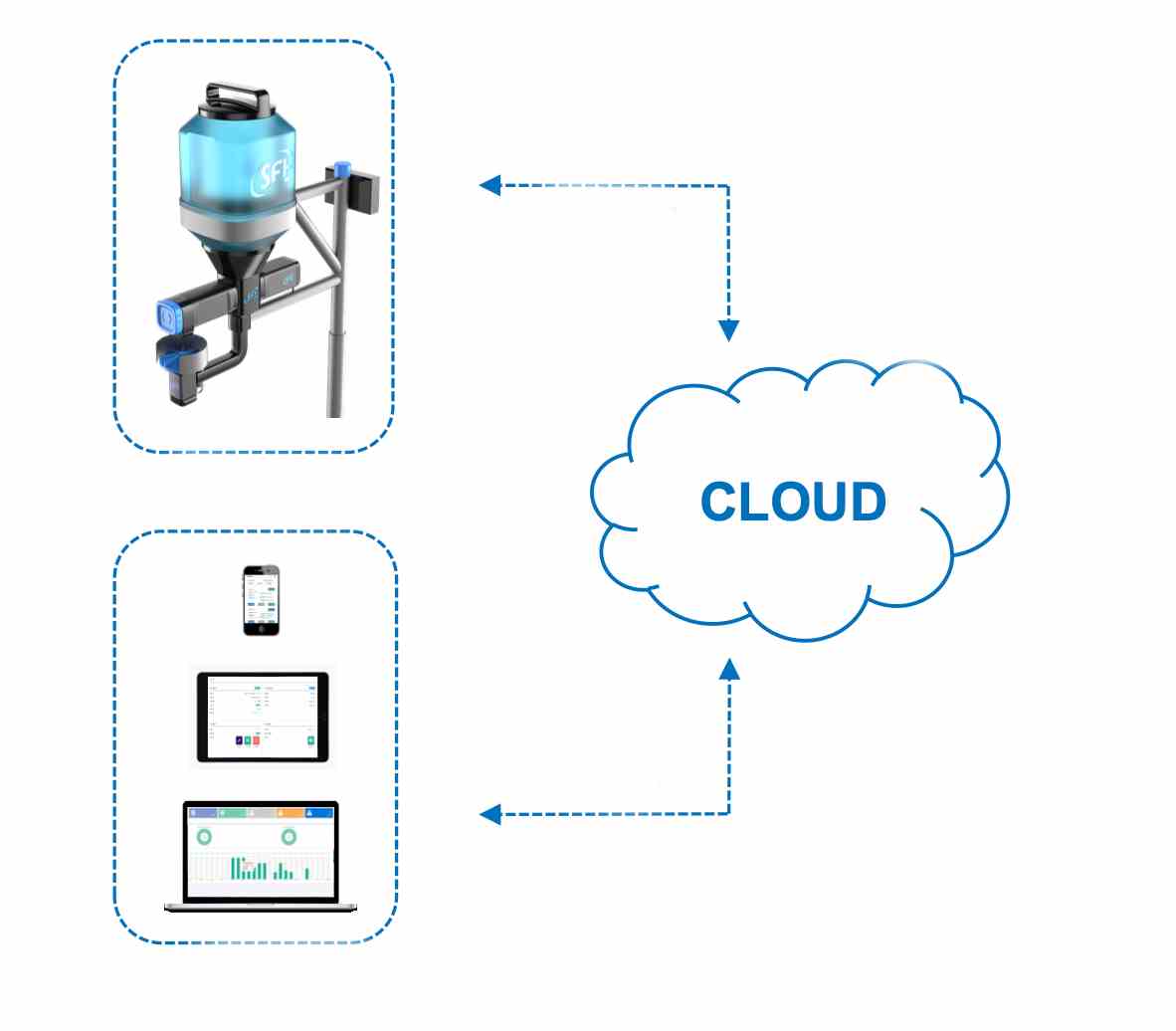

Digital feeding machine acquisition system, remote monitoring and management.

Development process:

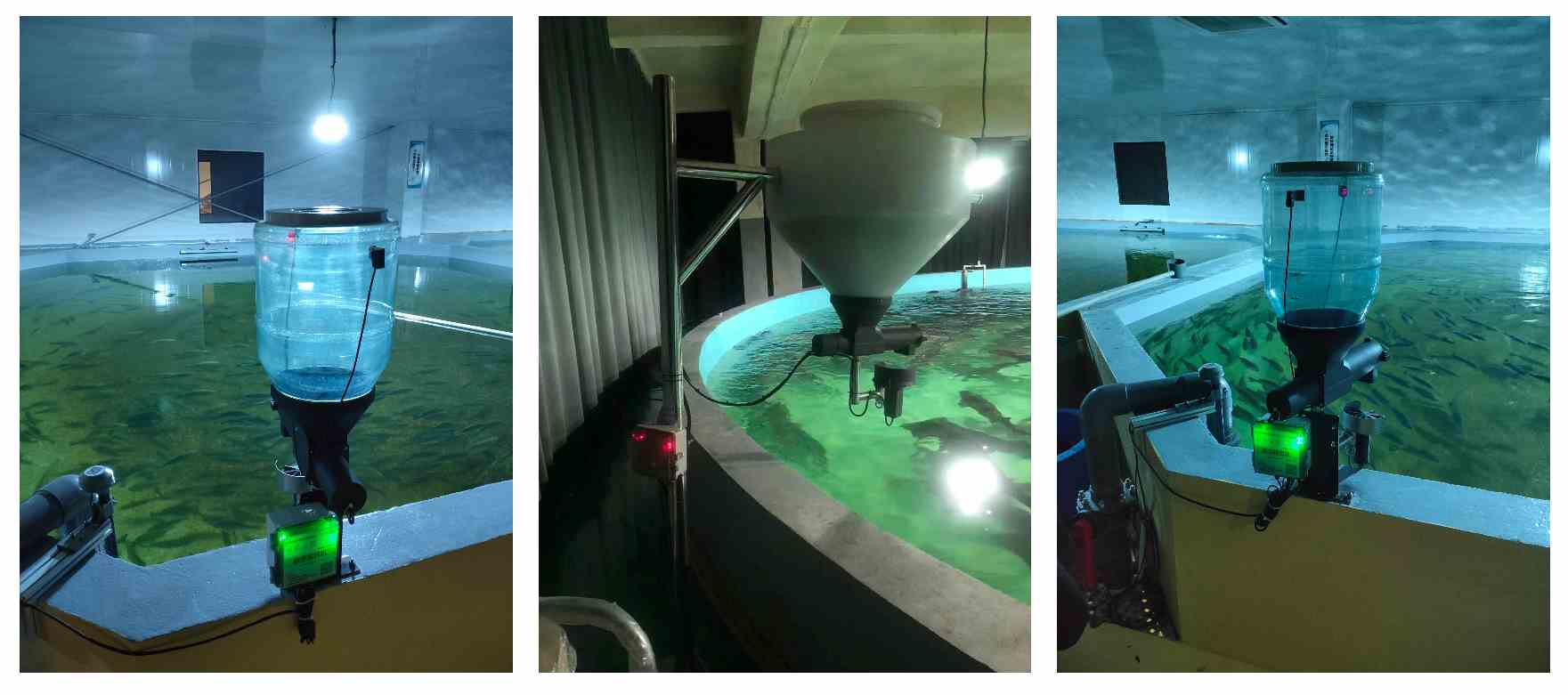

During the development phase, the LKK Design team worked closely with technicians from Dalian Smart Fishery Technology Co., Ltd. to complete the research and development and testing of the equipment. We pay attention to every detail to ensure the stability and reliability of the equipment. After many trials and improvements, the final intelligent feed machine has met the expected goals in terms of performance and user experience.

Technological innovation:

The technological innovation of this intelligent feeding machine is mainly reflected in the following aspects: First, the design of the replaceable dumping tray makes the equipment more flexible and adaptable to the needs of different food; Secondly, the special connection structure makes the tray can be disassembled and washed quickly, which is convenient for daily maintenance. Finally, the digital feeder acquisition system transmits data to the cloud platform through the mobile network, allowing users to view and control production data anytime and anywhere. In addition, the intelligent feed machine also has a high level of protection and full-body brine flushing function, which can be stable in the salt spray environment for long-term operation. At the same time, the humanized design of the equipment makes the operation simple and convenient, and the user can master the use of skills only through simple training.

Main technical parameters:

Supply voltage :DC24V(DC18-36V wide voltage);

Operating current: the average operating current of the equipment is about 0.6A;

Equipment power: according to different particle specifications, between 10W-15W;

Feeding specification :1-16mm(pellet bait);

Feeding speed :0-4r/min;

Dumping distance: according to different particle specifications, the distance is between 0-3m;

Bait bucket specifications :6L/25L/40L/80L/160L;

Management control mode :Web, Pad, APP;

Operating environment: long-term stable operation in salt spray environment;

Protection level: The whole fuselage can be washed with salt water;

Equipment maintenance: According to the use of the discharge plate and baffle regularly clean, when the feeder is not in use, more than 3 days need to pour the bait in the feed bin out of the feeder, to prevent the bait spoilage.

In addition, the production data collected by the digital bait feeder is quickly and efficiently transmitted to the “intelligent feed cloud platform” through the mobile network (4G/5G), so that users can view and control it through the mobile management terminal (computer, Pad and mobile phone).

In general, this intelligent feed machine is not only an efficient and intelligent equipment, but also a humanized and forward-looking product. It fully considers the needs of users and the use of the environment through innovative design and advanced technology to bring real value to users. In the future, I believe that this product will play an increasingly important role in the modern aquaculture industry to promote the sustainable development and progress of the industry step。

We provide one-stop product development services:industrial design, mechanical design, rapid prototyping, small batch production,DFM,Mold design and manufacturing, Validation&Certification, mass production, etc